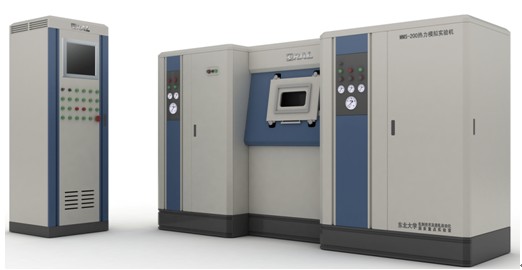

MMS-200 Thermal Simulation Testing Machine

Name: MMS-200 Thermal Simulation Testing Machine

Manufacturer: The State Key Laboratory of Rolling and Automation, Northeastern University

Purchasing Date: September, 2006

Main Specifications:

Maximum heating temperature: 1700 ℃ or sample melted;

Maximum pull pressure: 98kN / 49kN;

Maximum torque: 100Nm;

Maximum stroke: 100mm;

Maximum loading speed: 1000mm / s or 2000mm / s (tensile or pressure);

Steady temperature control accuracy: ± 1 ℃;

Force control accuracy: 10μm;

Sampling frequency: ≤10kHz;

Actual maximum strain rate: 100s-1;

Minimum time under constant strain rate deformation mode: 18ms;

Minimum time under non-constant strain rate deformation mode: 6ms;

Common Accessories: Operation Rules for MMS-200 Thermal Simulation Machine

Main application areas:

Thermal simulation test machine is sophisticated research equipment. Many experimental studies on the steel material processing and forming are conducted through thermal simulation machine, such as sensitivity studies on CGHAZ reheat cracking; hot ductility of carbon steel in the continuous casting; the effect Cr and Mo on the phase transition performance of dual-phase steel in the process of hot rolling; research and development on the new generation steel materials.

Main functions:

MMS-200 Thermal Simulation Machine is a high-precision and high-performance multi-functional simulator, with multifunctional simulation and experiment capacity. It can simulate temperature, stress, strain, displacement, force, torsion angle, torque and other parameters, and can be applied to various experiments. Specific experimental types are as follows:

- Tensile test;

- Single-pass compression test;

- Plane strain compression test;

- Multi-pass compression test;

- Dynamic CCT experiment;

- Dynamic recrystallization experiment;

- TMCP experiment;

- Strain induced experiment;

- SICO test;

- Stress relaxation PTT experiments;

- Non-strong zero temperature (NST) measurement test;

- Non-ductility temperature (NDT) measurement experiment;

- Heat Treating;

- CCT static test;

- Casting experiment;

- Static recrystallization experiment;

- Welding thermal cycle test;

- SH-CCT test;

- Welding diffusion test;

- Resistance butt welding test;

Person in charge of the equipment: Chen Yingying

Ways of contact:

Tel: 024-83690365 /024-83690363

E-mail:

Location: Factory building of RAL