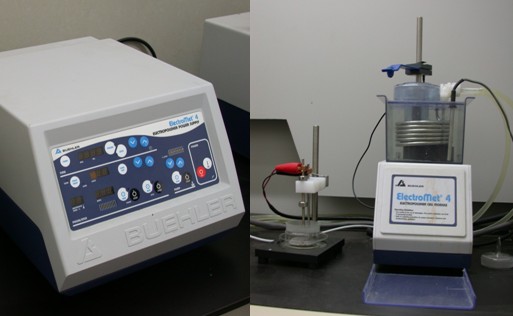

Name: Electrolytic polishing etching machine

Manufacturer: American Buehler Instrument Co., Ltd.

Purchasing date: November, 2008

Main Technological Indicators:

1. Parameter memory function; polishing time: from 0 to 59 minutes

2. Etching time: 0 to 59 seconds, increment: one second;

3. Maximum sample height: 12.7 cm; polishing and etching can be automatically switched;

Equipment model: Electromet 4

Main application areas: It is a metallographic sample preparation equipment that integrates electrolytic polishing and etching functions together. It applies to factories, universities and colleges, research institutions and other laboratories. The Instrument adopts electrochemical principle to prepare metallurgical samples. Metallographic sample prepared by electrolytic polishing and etching could avoid the distortion layer caused by mechanical polishing, so there is no false appearance in organization. Therefore, it is the best method to prepare nonferrous metal samples, like titanium, aluminum, copper and super alloy.

Main functions:

Electrolytic polishing etching machine is an effective polishing and etching means for alloy materials, which includes stainless steel, aluminum, titanium and copper-based alloys and other irregularly shaped samples.

Related Links:

Buehler's website:

http: //www.buehler.com/productinfo/gp1.htm

Person in charge of the equipment: Xue Wenbin

Location: Room 131, RAL

Ways of contact:

Tel: 83686420

E-mail:

Operation Rules

- General Rules

- Before operation, relevant training or learning over the rules and safety regulations are required. If the operator haven’t operated for a long time, he or she shall relearn the rules and safety regulations.

- Carefully check whether the labor protection products are suitable. Put on labor protection appliances before operation.

- Pay attention to safety utilization of electric power. Do not touch switches, sockets, etc. with wet hands. The power supply of the equipment should have reliable grounding device.

- Turn off the power supply, faucets and valves after usage, and clean the equipment with a rag.

- Containers holding the solution must be labeled to indicate the ingredients, preparation persons, production date and expiration date.

- Electrolyte and extract liquid shall be prepared inside a ventilated cupboard.

- Abandoned electrolyte, extract and other emissions should be discharged correctly according to the provisions.

- Be careful while using chemical solution. If chemical solution is accidentally splashed onto the body, rinse immediately with plenty of water; if the solution is accidentally slashed into the eye, flush with water first, then go to the hospital.

Operation Rules

- Power on the machine.

- Adjust proper voltage parameters and electrolytic polishing time.

- Slowly pour the electrolyte into the electrolytic cell. Be careful not to splash it on the body.

- Put the sample on the electrolysis baffle orifice. Be careful to choose the right orifice, otherwise the sample would drop through it if the orifice is too large. Take and place the sample by forceps or wear acid-proof gloves. Don’t directly take it by hand.

- Run electrolytic polishing pump. Observe the rate and quantity of the overflowing electrolyte from the baffle hole. Adjust the intensity of the pump according to the circumstance.

- Press ‘START’ to polish. After polishing, the machine will stop automatically. Stop the electric polishing pump.

- After experiment, pour out the electrolyte carefully. Electrolyte usually has to be stored in the grinding mouth bottle.

- Cut off the power supplies. Clean the working environment. The experiment ends.