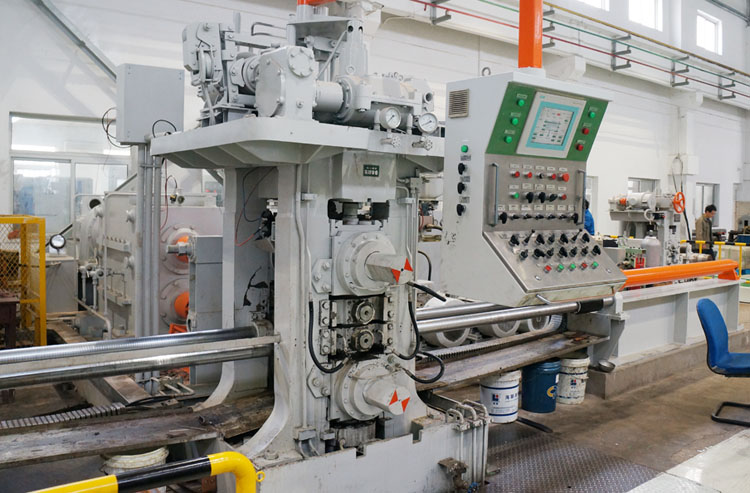

Four-high Cold/Warm Mill with Hydraulic Tension

1. Function

Four-high Cold/Warm Mill with Hydraulic Tension adopts hydraulic permanent tension and online resistance heating technology to realize experimental research on cold or warm rolling of tensile strip steel. It is particularly applied to the study and development of cold-rolled strip variety, technology and equipment based on short cold-rolled metal produced from small smelting furnace. The equipment can meet the rolling demand of high-strenth steel, high-silicon steel, titanium alloys, magnesium alloys and many other difficult-deformation strips.

2.Technological (Equipment) Process

Single piece test strip→cutting→annealing→surface treatment→clamping→first reservible rolling→size determining and sample cutting→second reservible rolling(option)→process lubrication (option)→sample marking→data collection→ printing report

3. Technical Indicators

Sample size:

Blank size: Hmax×B =2.0×100~200mm,

Product size:hmin×B =0.12×100~200mm

Supporting roller size: Ø330~350×300mm

Workig roller size: Ø105~150×300mm

Thickness control: EAPC+HAGC

AGC hydraulic cylinder parameters: Diameter: Ø200mm, stroke: 50mm, working pressure: 18.5Mpa

Main motor power: 18.5kW, DC440V

The maximum rolling force: 1200kN

Rolling speed: 0 ~ ± 0.3m / s

Hydraulic tension range: 2.5 ~ 100kN

Warm-rolling heating power: 150kW

Warm-rolling heating temperature: 100 ~ 800 ℃

Technical (Safety) Operation Rules

- This mill consists of two hydraulic cylinders controling its left and right tension and a mainframe. It must be operated by specially-assigned people when it is in operation. Before starting the machine, power systems, pump stations and operating box value should be checked and adjusted correctly.

- The mill power switch and pump station switch should be turned on before operation, and check whether mechanical transmission and clamps work normally. Obstacles and foreign substance on rollers should be cleaned up.

- The roll bite should be adjusted to be the same with the thickness of billet. Only with a proper pressing distane, the machine can clamp the billet and operate smoothly. Over-loaded pressing is never allowed.

- Clamp the billet in a certain order. Ensure that the roll bite, thickness, tension and rolling speed be consistent with normal rolling requirements.

- During operation, operators should always stick to their posts and observe the mill’s operation condition. Once broken belt, billet off track or other emergencies occur, operators should stop the mill immediately.

- Don’t put foreign substance on the operation stage. Don’t use tools to press on or crash the switch. Always keep the operation stage clean.

- Operators are not allowed to stand in front of the rolling cramp, so as to avoid being injured by the broken belt.

- After rolling, lift up the roller and restore all switches to null position.

- After testing, clean the working evironment and fill in the operation record.