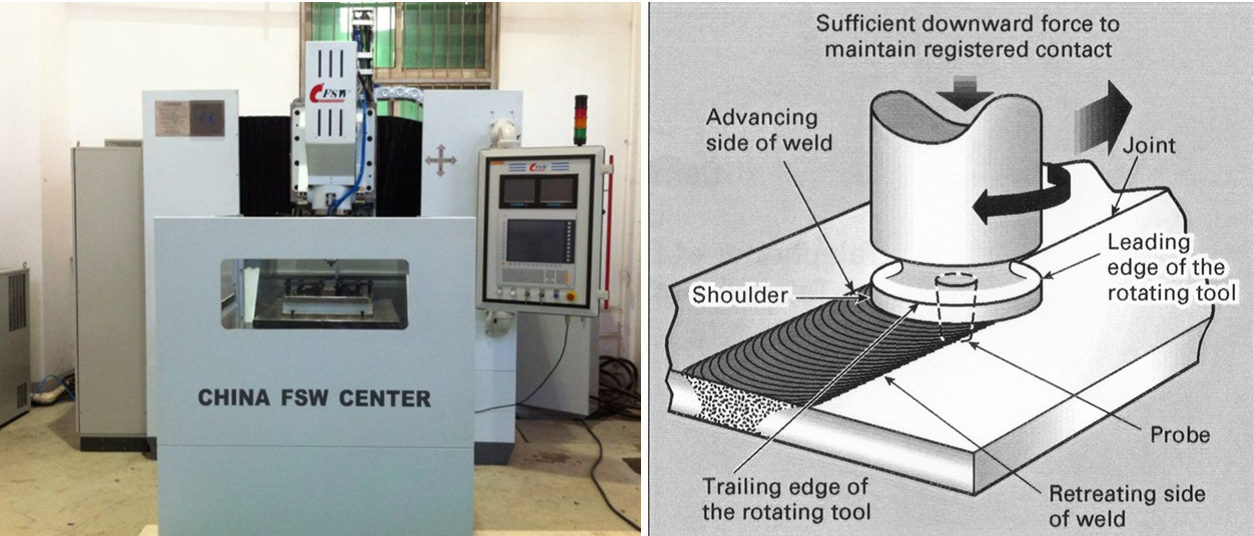

A few days ago, a new type of gantry friction stir welding machine, purchased by RAL, has been installed and debugged in RAL. This device is China's first friction stir welding machine that can be used to connect steel alloy. What’s more, it can also be used to weld various types of aluminum alloys, magnesium alloys and copper alloys. Contrasted with the conventional fusion welding, friction stir welding joint has extremely good mechanical properties. Currently, overseas countries have tried to apply friction stir welding to the connection of steel alloys in automotive and petrochemical fields. RAL has conducted friction stir connection test on high- strength X120 pipeline steel and TWIP with high carbon equivalent and high alloy, and gotten welded joints with excellent toughness. Friction Stir Welding is ideal for some metals which traditional fusion welding cannot connect. Therefore, we will further expand the research objects, and carry out welding research on more weld steel materials difficult to be welded.

Friction Stir Welding (FSW), invented in 1991 by the British Welding Institute (TWI), is a new solid phase connection technology that differs from the conventional fusion welding. As the picture shows, the specific principles of FSW are as follows: a tool with a stirring pin and a shoulder rotates in a high speed to ensure its pin to insert into the workpiece seam. After the shaft shoulder touches the workpiece surface, the tool moves forward. Throughout the process, with the agitation of the stirring pin, weld metal has a strong plastic deformation, and with the high-speed friction between the shoulder and workpiece surface, a lot of frictional heat is generated. Both of them lead to dynamic recrystallization, and thus form homogeneous isometric fine-grained structure. Compared with traditional welding, the welding temperature of FSW is lower than its metal smelting point and higher than the recrystallizing point. Thereby, it avoids heat cracks, pores and slag and other defects while welding, and the welding deformation and stress are also relieved. What’s more, with no welding arc light or smoke pollution, FSW is a new type of environment-friendly welding technology. Currently, FSW has made considerable development in the aluminum alloy field, such as Aluminum-alloy inner walls of high-speed rail and light rail cars, rocket fuel tanks, the connection of aircraft floor.