On the basis of domestic industrial production lines, RAL successfully realized the industrial mass production of high heat input welding steel with 100 ~ 500kJ / cm heat input during preliminary work. What’s more, domestic research institutes and steel companies are also working on the research and development of high heat input welding steel. In the next few years, high heat input welding steel in China will come to the stage of large-scale industrial applications. However, there is a gap in the production of corresponding materials. Currently, the highest heat input of welding wire produced by domestic enterprises is 100 kJ / cm, and the demand for 100 ~ 500kJ / cm heat-input wire relies on imports totally. Due to technological blockade and monopolized price of imported welding materials, downstream industries in China have to increase their welding costs, which is not conducive to the development of China's economic construction. To change this situation as soon as possible and timely produce matching welding material when the high heat input welding in China comes to universal applications, it is necessary to implement basic research and development on welding material which can bear 100 ~500kJ / cm welding heat input.

According to the existing welding equipment type in domestic enterprises, high heat input welding steel adopts flux cored wire in welding. While the product equipment for flux cored wire is often applied to the production of conventional welding wires. The main reason is that researches on acicular ferrite which is beneficial to strength and toughness and multi-orientation bainite nucleation mechanism are relatively weak. Currently, high heat input welding materials with yield strength less than 550MP may adopt acicular ferrite, and those with yield strength over 550MP may adopt multi-orientation bainite to ensure strength and toughness. Although mechanisms forming such organizations have more than six kinds around the world and each mechanism can explain some phenomenon, there are always some counter examples cannot be explained. Therefore, people have not reached a consensus on the mechanisms.

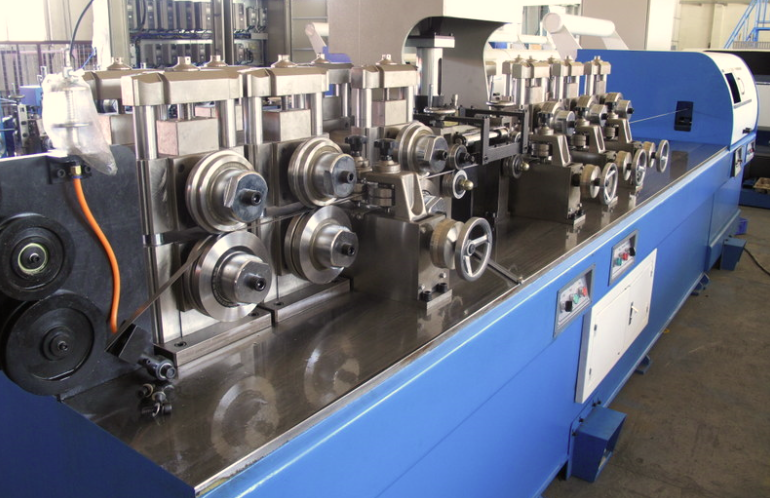

RAL has introduced an advanced flux-cored experiment line. While researching and developing high heat input welding material, RAL also pays attention to basic theoretical research, mainly including: welding metallurgy conditions and control conditions, kinetics, and thermodynamics of selective precipitation of occluded foreign substance in weld metals; the influence law of occluded foreign substance in weld metals on the formation and transformation of high strength and toughness organization; the nucleation mechanism of intragranular acicular ferrite and multi-orientation bainite. The research findings will be able to provide a theoretical basis and technical support for the development of welding materials with over 100kJ / cm heat input.