Product quality indicators of hot rolled plate include mechanical properties and dimensional accuracy, but with the current fierce market competition, users have higher requirements for the surface quality of steel plates, strictly forbidding pockmarked face, pits / pitting and piebald and other surface defects. Therefore, surface quality has become one of the major quality indicators of the plate, and attracted extensive attention from the steel mills and downstream users. According to the feedback from the downstream shipyards, spotted defects seriously affect the surface finish of the ship plate after painting. Accordingly, Chongqing Steel Medium Plate Mill proposed research demand order to tackle the issue of piebald defects on the ship plate.

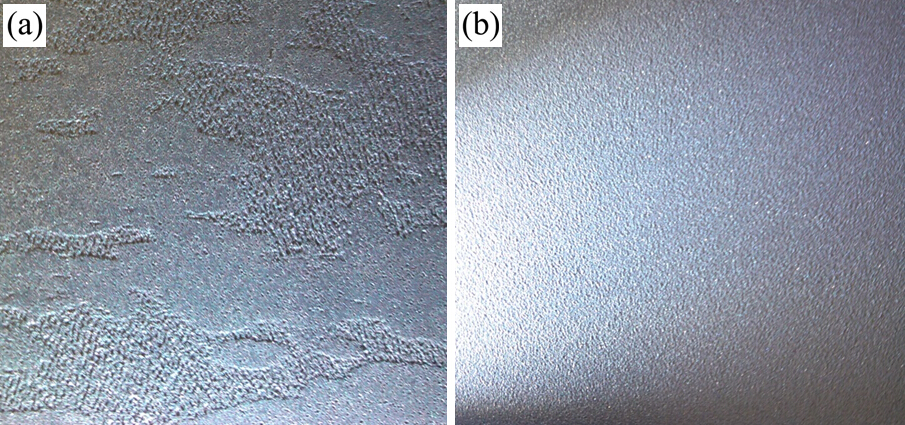

Macro view of the medium plate after shot blasting:

(a) Before (b)After

The thickness of the iron scale has taken on inhomogeneity macroscopically, while microscopically showing fluctuations in numerous cracks and the thickness of iron scale on the surface, even partial multilayer stacks of iron scale. Researchers working on iron scale in RAL, based on the analysis above, determined to dig in by a three-pronged approach concerning steel composition, hot rolling equipment and techniques, to conquer the problems of piebald defects. Through the integrated application of the means above, the problem of piebald defects has been fundamentally solved. After the new process, the commuted rate for piebald plate has been reduced to 2.5%, a massive cut compared with that of the second and third quarter in 2013, which was accumulated to 36.9%. It has made prominent achievements in terms of improving the surface quality of the hot rolled plate.