Steel material is one of the most indispensable metal raw materials in the construction of national economy. Because of large volume of consumption, it has a significant impact on the environment and resources. Therefore, the development of steel material with "long life, recyclability, and high-performance" is an important method for the international community to cope with environmental deterioration and resource depletion. Replacing the galvanized AHSS (Advanced High Strength Steel) with stainless steel can achieve nearly 100% recycling and reuse, which thereby relieves the pressure of insufficient reserves of zinc and reduces devastating effects on the environment caused by dust emissions in the process of recycling galvanized sheets. However, conventional nickeliferous stainless steel is daunting for users due to its high cost; traditional energy-saving stainless steel, such as Ferritic and Martensitic stainless steel, is acceptable in terms of cost, but its strength and mechanical property has obvious defects, esp. in plasticity and toughness, which result in rigid limitations for its applications.

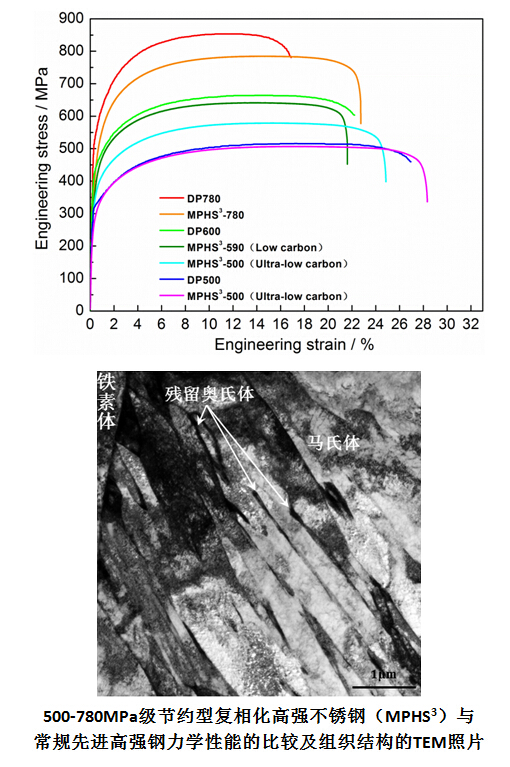

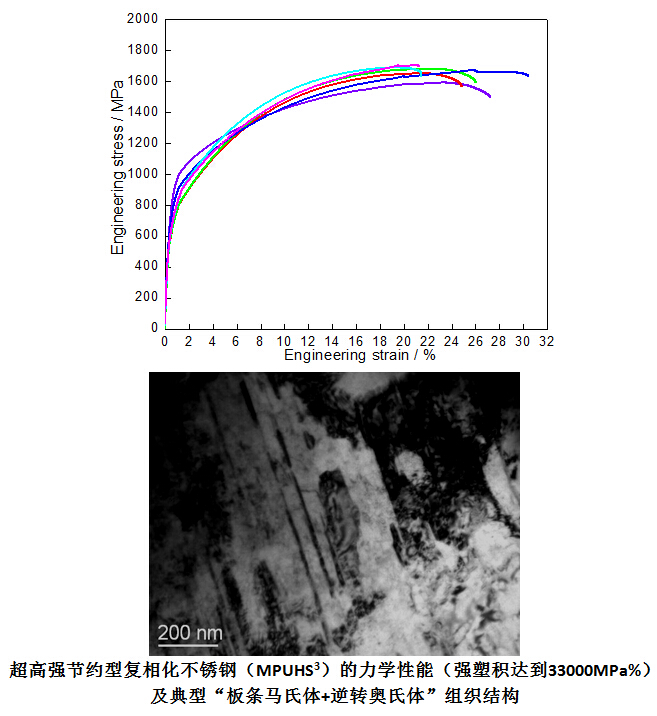

How to develop a new steel material with anti-corrosion, low cost and high-performance? It has always been an ideal for the world steel industry to strive for. To achieve this goal, the RAL stainless steel group led by Professor Liu Zhenyu cooperated with Associate Professor Wang Lijun from Material and Metallurgical College. Through exploring the microstructure evolution and alloy element diffusion in the process of thermo-mechanical treatment, they found out the toughening mechanism of energy-saving stainless steel; successfully developed new rolling, cooling and the "Thermoforming + Q & P" integrated preparation technology for energy-saving multi-phase high strength stainless steel; and developed prototypes of energy-saving multi-phase high-strength stainless steel with its mechanical properties far better than the conventional AHSS, such as the energy-saving multi-phase high-strength stainless steel with a chemical composition of Ferrite, which can replace DP590 and DP780; and energy-saving multi-phase high-strength stainless steel with Martensitic stainless steel components, strength reaching 1200MPa-1600Mpa and plasticity over 20%. These multi-phase high-strength and ultra high-strength steel can substitute advanced high-strength hot galvanized steel while the raw materials and production cost are even lower than traditional AHSS. The energy-saving multi-phase high-strength stainless steel and its preparation technology have aroused great attention from many stainless steel manufactures such as TISCO, Great Wall Automobile, Yutong Buses, and so on. All of them are actively implementing the industrial trial-produce and trial-application of prototype components.

The study mentioned above has made a new breakthrough for the variety of stainless steel structure. The two constitute new variety system for multi-phase high strength/ultra-high strength stainless steels, and have broken the application bottleneck of energy-saving stainless steel in key areas like transportation, load-bearing structure, and even military. They can also provide affordable and high-performance stainless steel products for the development of national economy. This study will further enrich the theory of physical metallurgy of stainless steel production, promote the development of China's stainless steel production technology, and its industrialized application is bound to contribute to the construction of China's circular economy.