In November 2015, the development project of rolling line automatic control system and plane shape control technology of rolling line transformation project of Tangshan Steel Plate Com., Ltd. entered the debugging stage, and in May 2016, the automatic control system and plane shape control technology passed the acceptance check and interim check, respectively. All technical indicators of automatic control system reached international advanced level, and the rolling yield of flat shape control increased 0.88% on year-on-year basis.

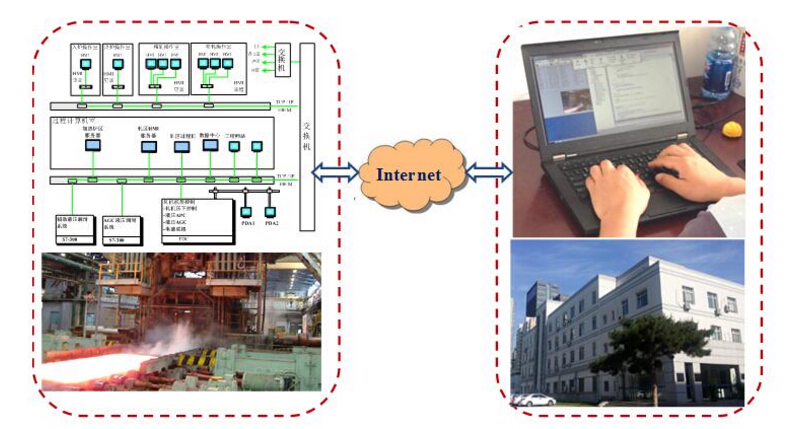

In the design and debugging process of the project, the project team has developed a series of key technologies, such as the 19 plane shape control technology, intelligent optimization of model parameter, self-adaptation control of end to end thickness. Among them, the development and application of the remote monitoring and fault diagnosis technology in the automation system of production line realized remote monitoring, data acquisition, fault diagnosis, parameter optimization and remote debugging functions of the rolling mill automation control system for the two rolling lines in Tangshan Steel Plate Com., Ltd.

After field debugging, RAL plate rolling automation project group of Northeastern University could shorten problem analysis time and reduce the chances of production halt, through remote quick response to on-the-spot technical problems and production accidents. This would not only provide effective technical guarantee for the steady operation of control system, improving control accuracy, and realize technology optimization, but also build a good platform for later maintenance and collaborative innovation of enterprise projects.