With Hebei Province taking the lead in implementing the "Ultra-low Emission Standards for Air Pollutants in the Coking Chemical Industry" and "Ultra-low Emission Standards for Air Pollutants in the Iron and Steel Industry", the national environmental protection has entered the most stringent stage in history, and the steel heat treatment field has also faced severe challenges. More and more coke ovens have been shut down, coke oven gas is becoming a scarce resource. The gas for blast furnace or converter without coke oven gas mixture has a low calorific value, so it is difficult to burn safely, and has not been successfully and steadily used in high-quality heat treatment furnaces. The use of natural gas is not technically mature in many areas, and the price for nature gas is high, so the cost for using natural gas is high. Therefore, it is of great significance to use a low calorific value blast furnace or converter gas on a heat treatment furnace to achieve safe and ultra-low emission heating.

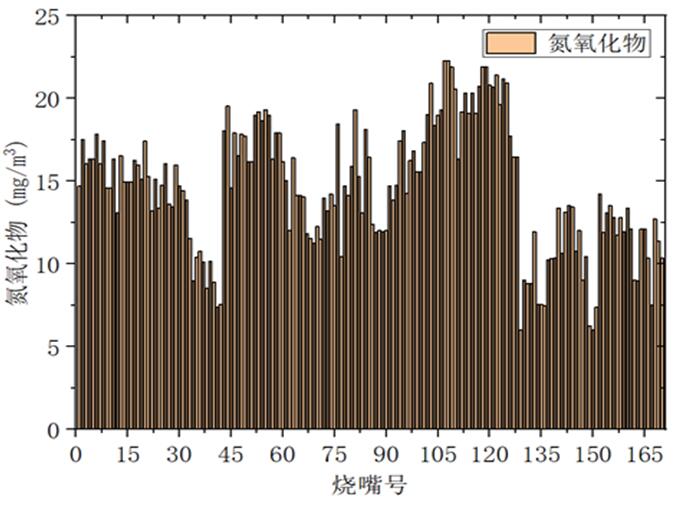

In 2018, the heat treatment line project of Hebei Puyang Iron and Steel Medium Plate Plant undertaken by RAL successfully broke through the ultra-low emission heating technology for low calorific value blast furnace gas, and developed a low calorific value gas radiant tube burner device and a complete set of heat treatment furnace equipment. The heat treatment furnace was successfully ignited in November, and the stable production of normalizing, quenching and tempering processes has been realized. The measured nitrogen oxides is 7-25mg/m3, which is far less than the requirement of the national standard ultra-low emission 150mg/m3, and has successfully solved the problems with low calorific value gas, such as difficult to ignite, unstable burning, and deflagrations, providing an effective solution for the problems faced by steel companies like lack of coke, and excessive emission of nitrogen oxides due to national environmental protection upgrades.

▲Roller-hearth heat treatment furnace

▲ Burner device

▲Burner Nox measurement (8%O2)

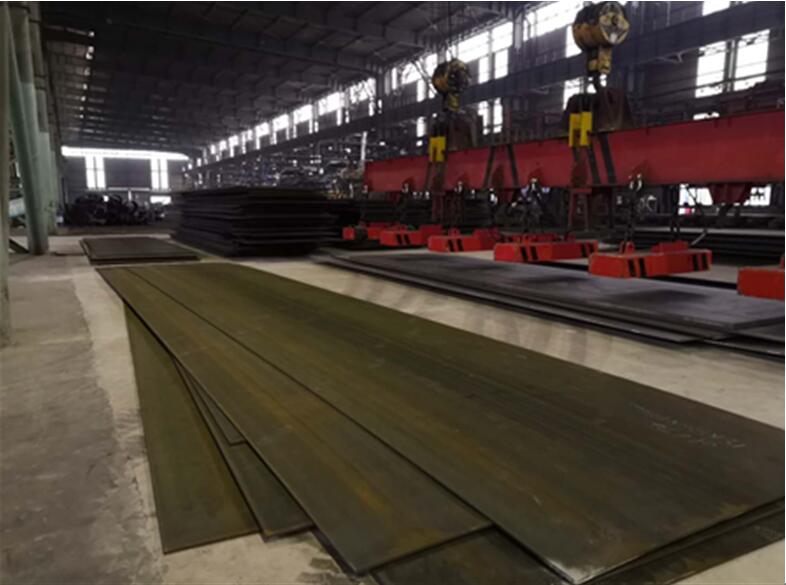

▲Low calorific value gas roller-hearth heat treatment furnace

In this project, RAL has undertaken the development, supply and commissioning of roller-hearth heat treatment furnaces, multi-function roller quenchers, complete sets of water systems and electrical automatic control systems. The equipment technology has the following characteristics and innovations:

(1) The working temperature of the heat treatment furnace is 300-980 °C. The low-calorie gas ultra-low emission radiant tube burner is used for pulse combustion, and the special combustion control system and control strategy for low calorific value gas are established. The furnace temperature control accuracy is within ±5 °C, realizing successful and stable application of low calorific value gas on heat treatment furnaces.

(2) The quenching machine has the functions of quenching and NAC, and can meet the requirement for the high-flatness production of 6-100mm steel plate. The quenching machine, integrated design of the water system, and integrated control of the whole process of water, and the use of water have an integrated control system, which significantly improves the process stability and rapid response of the quenching process. ;

(3) The heat treatment production line adopts multi-level fully automated system design and integrated control of heating-quenching process and steel plate transportation process, and realizes full automation of production operation and precise execution control of process, providing reliable basis for the upgrade of Puyang Steel's products.

▲Multifunctional roller quenching machine

▲Quenched steel plate produced by heat treatment line