Under the guidance of Academician Wang Guodong, and with the basic research on the principle and mechanism of fine-grained steel by Dr. Wang Chao, the academic backbone in hot-rolled steel, fine grained steel research team of the State Key Laboratory of Rolling and Automation (RAL) of Northeastern University, has successfully discovered the rule for the evolution of 2nd-phase particles and the mechanism of induced phase deformation and solved related scientific problems. On such basis and combining laboratory research and industrial trial production, the team has broken through the core technology of composition-smelting-rolling-cooling whole process management performance control, and so far has successfully realized the mass production of fine grained steel process technology in the field of rebar products, and achieved break-through progress in research. The research makes full use of the second phase of oxygen/sulfur/nitride particles to induce fine crystal action, exerts the fine crystal strengthening mechanism, reduces the large amount of microalloying elements, reduces the alloy cost and production difficulty, and forms stable industrial production technology. At present, the fine grained steel technology has been applied to the industrial production of 12-36mm HRB400E seismic rebar, with good structural performance and remarkable cost reduction effect. Based on the research, relevant process technology innovation has been awarded 5 national invention patents and 4 international patents, forming an industrialized complete set of process technology, which can provide a package of systemic solution for enterprises.

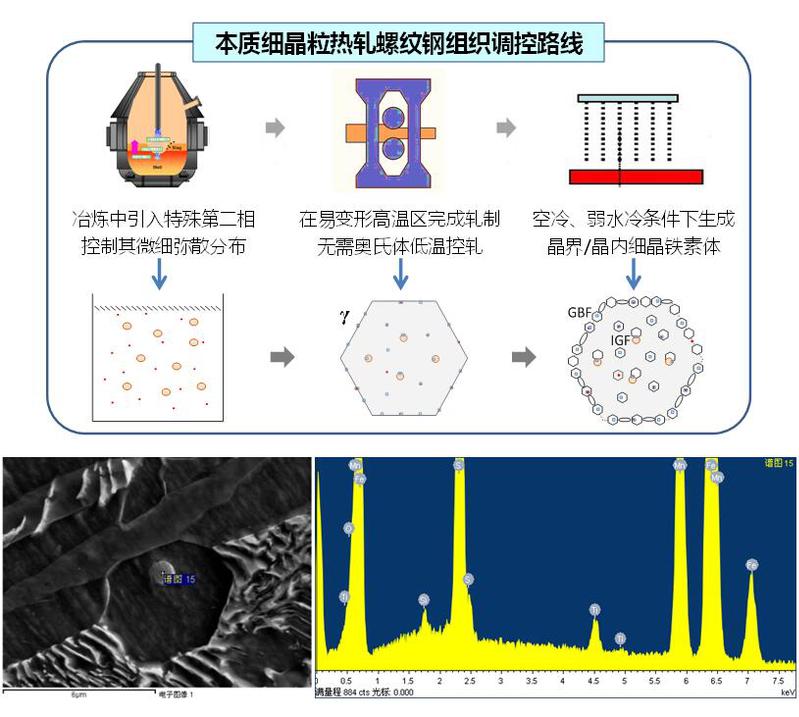

Rebar is the largest and most widely used steel in construction steel. For the steel industry, rebar products are relatively simple to produce and should use ingredients and processes as simple as possible to achieve high quality products. In 2018, China implemented the new national standard GB/T 1499.2-2018 for rebar, which strengthened the requirements for metallographic organization of products. In order to meet the requirements of the national standard, each rebar producer further strengthened the use of vanadium or niobium microalloying technology, which not only caused an increase in production costs, but also led to huge consumption of precious alloy resources. In response to the organizational performance regulation requirements proposed by the new national standard, especially for large-scale products, it is urgent to carry out technological innovation to achieve economic and green production of high-quality rebar. In the mechanism research, Dr. Wang Chao identified the control mechanism of the dispersion of fine second phase particles through the thermodynamic analysis of the precipitation of oxygen/sulfur/nitride during smelting, solidification and rolling, examined the mechanism of body coarsening and microstructure transformation behavior of the austenite under different thermal deformation conditions, analyzed the mechanism of oxygen/sulfur/nitride inducing fine-grain phase deformation, and clarified the interaction mechanism between second-phase particles and microstructure evolution, providing theoretical support for process technology development. In the industrial transformation practice of basic research results, combining production, study and research and based on the systematic sampling analysis of the evolution law of inclusions in the rebar industrial production process, the research team explored the optimal content range of oxygen, nitrogen and other elements and their control methods, examined the absorption rate of titanium and other elements and their influencing factors, determined the optimal way to form oxygen/sulfur/nitride forming elements, and explored the essentials of composition and production rhythm control under 150t converter conditions. So far, the research team has successfully solved the matching problem between processes at fast pace, the antegrade problem of continuous casting, and found out the influence of process parameters on performance under single-line rolling and split-rolling.

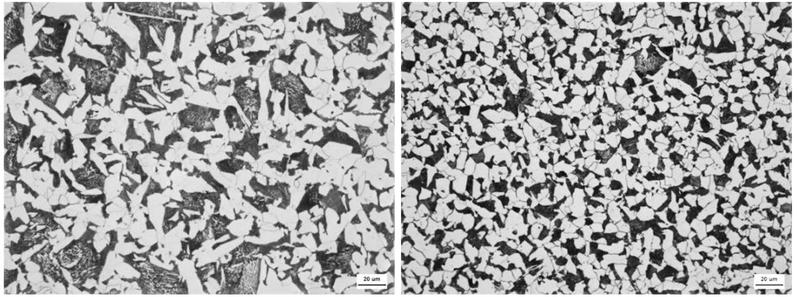

After several rounds of industrial trial production, the fine grained steel research team has solved the practical problems in different production lines, and opened up the whole process of smelting, continuous casting and rolling, In the multi-round continuous trial production process of more than 1,000 tons, the production process is stable and the product performance is excellent, thus the team has established a mature and stable industrial production process plan. Through the implementation of the fine grained steel technology, HRB400E rebar reduces microalloy consumption under non-controlled rolling and controlled cooling conditions, and the grain size is better refined by 1.5 or more compared with conventional vanadium-containing steel bars. On this basis, the team further developed Ti, Ti-RE, Ti-Cr, Nb-Ti, V-Ti, Ca-Mg, and Ti-Ca series of rebar products with different composition systems and process characteristics by adjusting the composition and process with different standards and specifications.

Structure of conventional vanadium -nitrogen microalloyed steel | Structure of fine grained steel |

In fact, Wang Chao started the basic research work related to the second phase particle induced tissue refinement mechanism and process of fine grained steel from his doctoral postgraduate stage. The study of fine-grained steel is mainly aimed at the major requirements of the uniformity control of the full-section structure of large-size, large-section or thick-type hot-rolled steel products. It is proposed to adopt a relatively reasonable composition design and process control means to achieve the refinement of the steel section structure and improve the comprehensive strength and toughness of steel materials. During his doctoral study period, Wang Chao devoted himself to the painstaking research for several years. He combined theoretical analysis with experimental research, not only spent much of his time in the lab with experimental smelting equipment to carry out in-depth study of the deoxidation element precipitation rules and organizational refinement mechanism, but also went into the steel enterprise production site, realizing the combination of basic research results and industrial practice. The research he carried out mainly includes: Facing the problem that the matrix structure or welding heat affected zone of large-line energy welding steel, hot-rolled pipe / type / rod wire and other steel is difficult to evenly refine, he introduced a dispersion of high thermal stability second phase particles into the steel, including titanium Oxygen/sulfur/nitride of elements such as calcium, magnesium, zirconium, boron, rare earth, etc., pinned grain boundaries and induced grain boundary/crystal phase deformation nuclei during heating, deformation and cooling, to obtain uniform fine crystal transformation structure and improve the overall toughness of materials. Targeting at the actual production demand of rebar, the fine grained steel research team of RAL remarkably brought the theoretical support of the basic research in the innovation chain of production, education and research into full play, flexibly and effectively used the diffusion of the second phase induced fine-grain strengthening mechanism, promoted the process technology innovation and progress through the breakthrough in basic research, and provided innovative ideas and technical routes for high-quality production of rebar. At the same time, relevant research breakthroughs have important reference value for realizing the fine-grained production of other steel products, and have great significance to the development and production of high-quality steel materials in China's steel industry.

Oxysulfide induced fine grain ferrite phase deformation nucleus

For technical communication:

Wang Chao: 15840169589

Email: chao_neu@163.com