Recently, a research result of Prof. Xu Wei’s team of RAL titled “Physical metallurgy-guided machine learning and artificial intelligent design of ultrahigh-strength stainless steel” was published by ActaMater. (2019, 79: 201-214). Shen Chunguang, a PhD. candidate from RAL, is the first author of this paper, Wang Chenchong and Xu Wei are the co-corresponding authors.

Material genetic engineering is a frontier in the field of materials that has emerged in recent years. It aims to reduce the cost and cycle of material research and development through the integrated application of integrated computing and database technology. With the development of integrated computing ideas and data mining technology, material genetic engineering has achieved remarkable results in the development of many new high-performance metal materials. However, since the composition process design of steel structural materials involves a large number of analyses of complicated coupling relationships and is subject to many controversial mechanisms, the design of steel materials based on material genetic ideas has always been an international hotspot and difficult problem in the field. With the advent of the era of big data, machine learning algorithms provide a feasible way to solve the process design and optimization under complicated systems. Although today's machine learning-based material design methods have yielded several success stories, the design approach used in most studies is simply to use machine learning algorithms to directly build a strong correlation between component/process and target performance at the statistical level, while ignoring the physical metallurgical information such as the most important microstructure characteristics in traditional material design ideas. This design method not only greatly hinders the understanding of the physical mechanism of the design results, but also leads to great dependence on the quantity of data, thus causing great difficulties for the design efficiency improvement and universal promotion of the model.

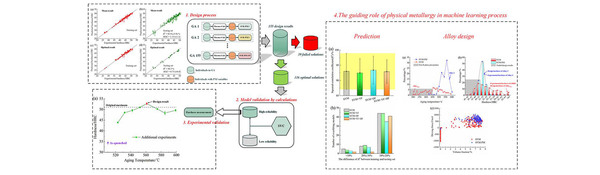

In view of the above bottlenecks in the design of steel materials based on traditional machine learning algorithms, the research team led by Professor Xu Wei proposed a machine learning method guided by physical metallurgy from the perspective of the fusion of physical metallurgy and machine learning algorithms. In this design method, through using the physical metallurgy parameters highly correlated with the strength to perform the dimension enhancement processing on the original data set, not only the physical metallurgical information can be integrated into the machine learning process, but also the original data inherent information can be fully extracted, and the data quality is improved. A predictive model with excellent generalization capabilities is obtained. Then the predictive model and the high-throughput genetic algorithm is optimally combined to form an efficient alloy calculation design framework. Based on the design framework, a new ultra-high-strength stainless steel is successfully designed under the 10^2 small sample data set. Compared with the original data set, the designed alloy system not only achieves strength improvement but also significantly reduces alloy content. In addition, compared with traditional design process without physical metallurgy, this new design method produces obvious improvement in model performance and design efficiency when physical metallurgical information is used in the machine learning performance prediction. The research results provide a feasible idea for the design of steel materials based on small sample machine learning algorithms and the improvement of physical interpretability in machine learning algorithms.

To read the article, please download the attachment or click on the link below.