The 2,000MPa high stress leaf spring steel, developed by Professor Yi Hongliang from the State Key Laboratory of rolling and automation, Northeast University, has meet the high standard of foreign leaf spring at the end of October 2020, then it was produced in Chongqing Hongyan Fangda automobile suspension Co., Ltd., and the test results meet the user’s requirements which provides technical support for domestic bus enterprises .

Leaf spring, as its simple structure, easy maintenance and low cost, is often used in the suspension system of various commercial and engineering vehicles. It bears the load impact of the wheel on the frame in the process of driving, reduces the violent vibration of vehicles, and maintains the stability of driving and adaptability to different road conditions. Due to the spring components of vehicle suspension repeatedly bear the stress load, so the fatigue durability performance of leaf spring matters. On the contrary, the design stress level of leaf spring on some vehicle models is as high as 1,300MPa. Therefore, it is necessary to develop new spring steel materials and the corresponding leaf spring manufacturing technology.

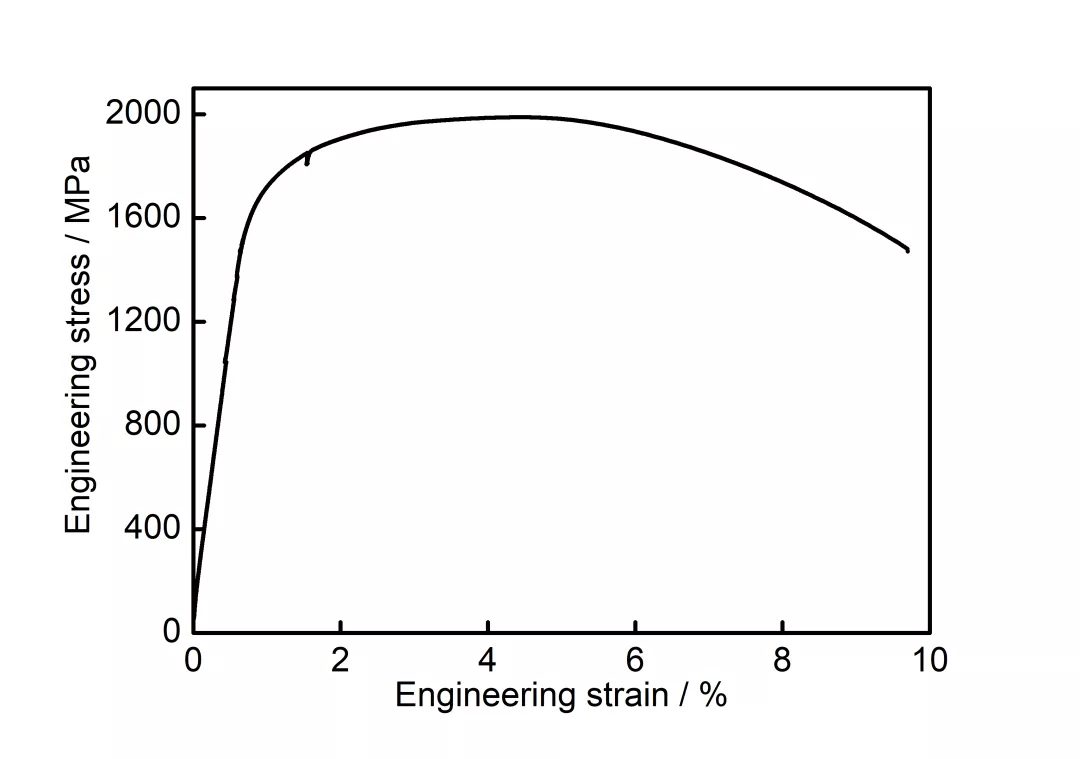

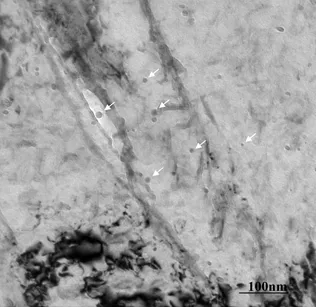

At present, some spring flat steel products are commonly used such as 60Si2Mn, 50CrV, 52crmnmov, etc. Of which, the yield strength is mainly 1,200 ~ 1,500MPa, and the tensile strength is 1,300 ~ 1,800mpa. Because the medium and high carbon alloy design leads to poor toughness of the material, which can not meet the demand of high stress leaf spring steel in automobile factory. Therefore, Professor Yi Hongliang’s team developed a new generation of 2,000MPa high stress leaf spring steel through vanadium microalloying design combined with unique heat treatment process, which greatly improved the martensite matrix toughness of spring steel by using nano vanadium carbide precipitation. According to the analysis of product samples, the yield strength of this newly-developed material is more than 1,700MPa, the tensile strength is more than 1,950MPa, and the impact energy of the U-shaped sample at - 40 ℃ is more than 40J, showing an excellent combination of strength and toughness. Compared with the existing leaf spring products, its strength and toughness can be increased by more than 20% and 80%. At the same time, the production cost of the parts almost does not increase. In the bench fatigue test, the leaf spring with 2,000MPa grade spring steel can maintain 250,000 times without fracture under the load with the highest stress level of 1,300MPa, showing excellent fatigue service performance.

▲Typical tensile curve of 2,000MPa leaf spring

▲Nano precipitated carbides in 2,000 MPa leaf spring

At present, Professor Yi Hongliang’s team works closely with steel enterprises, leaf spring enterprises and automobile enterprises to realize the rapid industrialization from science to technology and then to products, hoping to make great contributions to the improvement of comfort and lightweight of commercial vehicles in the future.