On January 13, 2023, Academician Wang Guodong/ Professor Yuan Guo's research team, from State Key Laboratory of Rolling and Automation of Northeastern University, published the latest research results in the plasticizing mechanism and organizational innovation design of ultra-high strength steel materials on the international top journal Science with the title of Ductile 2-GPa steels with hierarchical substructure.

Improving strength and plasticity at the same time has been a major theoretical difficulty in the field of steel materials for a long time, and also a bottleneck from basic research to technological innovation and application practice. Especially when the strength reaches the level of 2000 MPa, the plasticity decreases precipitously, and the uniform elongation is generally lower than 10%. The fundamental reason is that the initial high-density dislocation of traditional martensite is difficult to continue to multiply, and the micro-plastic deformation of the disordered geometric orientation structure is extremely uneven, which is easy to produce local stress/strain concentration. Therefore, it is still a great challenge to explore a new plasticizing mechanism and obtain 2000 MPa ultra-high strength steel with low cost and high plasticity by using the economical alloy design and simple and efficient preparation process.

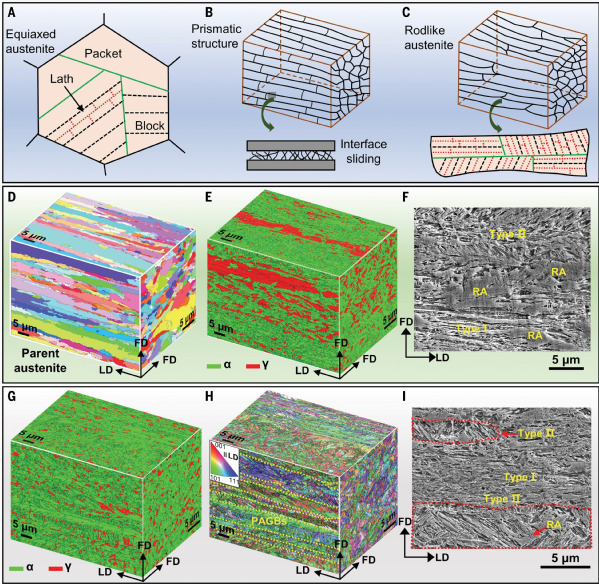

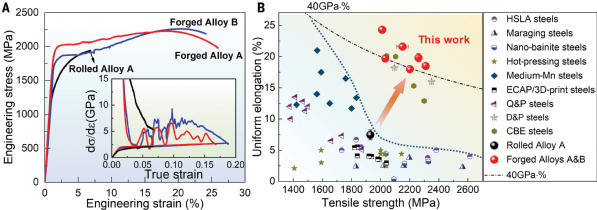

In the face of the above challenges, the research team innovatively puts forward a new synergetic plasticizing mechanism of martensitic topology structure design + meta-stable phase control, which has successfully prepared a series of low-cost C-Mn series new ultra-high strength steel, breaking the dependence of ultra-high strength steel on complex preparation process and expensive alloy composition, and breaking the performance boundary of the existing 2000 MPa grade martensitic high strength steel tensile strength-uniform elongation. Meanwhile, a simple and efficient preparation process is proposed to construct a new topologically double-ordered martensite and multi-scale meta-stable austenite nanoscale multi-level structure. The microstructure promotes the continuous high work hardening ability of the material, greatly improves its strength and plasticity, and achieves the ultimate properties of 1600~1900 MPa yield strength, 2000~2400 MPa tensile strength and 18%~25% uniform elongation by inducing a variety of strengthening and plasticizing mechanisms such as in-lath-plane slip, inter-facial plasticity and transformation induced plasticity (TRIP) during deformation.

Fig. 1 Structure design of new ultra-high strength steel

Fig. 2 Comparison of tensile properties between new ultra-high strength steel and other ultra-high strength steel

Breaking through the performance limit of metal materials is a hot and difficult point in the field of materials research in recent years. This research puts forward a new concept of martensite/austenite multi-level structure design, fully exploits the potential of materials, deepens the cognition and understanding of martensite structure control and deformation mechanism, and has great practical significance for promoting the preparation and application of low-cost, large-size ultra-high-strength plastic steel materials. This research not only provides a new research idea for the development and preparation of steel materials, but also other ultra-high strength plastic metal materials.

The authors of this paper are Li Yunjie, Yuan Guo, Li Linlin, Kang Jian, Yan Fengkai, Du Pengju, Dierk Raabe and Wang Guodong. The first author, Li Yunjie, is a postdoctoral fellow of State Key Laboratory of Rolling and Automation of Northeastern University. Professor Yuan Guo and Professor Li Linlin from State Key Laboratory of Rolling and Automation, and Professor Dierk Raabe from Max-Planck-Institute for Iron Research of Germany are the co-correspondents of the paper. Northeastern University is the first completion unit, and the Institute of Metal Research of the Chinese Academy of Sciences, the Xingcheng Special Steel Research Institute of CITIC Pacific Special Steel and Max-Planck-Institute for Iron Research of Germany are the cooperative participants. The research work was supported by the National Natural Science Foundation of China, the basic operating expenses of the central university and the China Postdoctoral Science Foundation.

State Key Laboratory of Rolling and Automation of Northeastern University has carried out research on advanced steel materials and processing technology for a long time, focusing on the construction of high-level scientific research platform, focusing on the forefront of science and technology in this field, promoting international cooperation and exchange, strengthening the cultivation of high-level talents, and paying attention to the application demand traction, and continuously deepening the basic research work. In recent years, new breakthroughs have been made in basic theoretical research and key technological innovation such as high-quality high-end steel materials, green processing technology and digital steel technology.