Austenitic stainless steel is widely used in civil, transportation, petrochemical, nuclear defense and other fields because of its non-magnetic, excellent corrosion resistance, easy welding, easy forming and good comprehensive mechanical properties. However, its yield strength is generally low (200~300MPa), which severely limits its application in the field of engineering structures. It is of great significance to improve the strength of austenitic steel through microstructure refinement.

1 Research overview

On the basis of relevant theoretical research, using conventional cold rolling and annealing processes, the coupling effect of deformation and phase transformation is used to realize the nanocrystallization of austenite structure, and the nano/submicron grain 304 cold rolled stainless steel plate is developed, with the yield strength of more than 1GPa. Through the control of microstructure, it can achieve a good match between strength and plasticity. The low temperature superplastic behavior and deformation mechanism has been studied. Based on the research results and the existing equipment conditions, the industrialization of high-strength plastic nanocrystalline 304 cold-rolled stainless steel plate has been realized.

2 Preparation of two block nanocrystalline 304 stainless steel

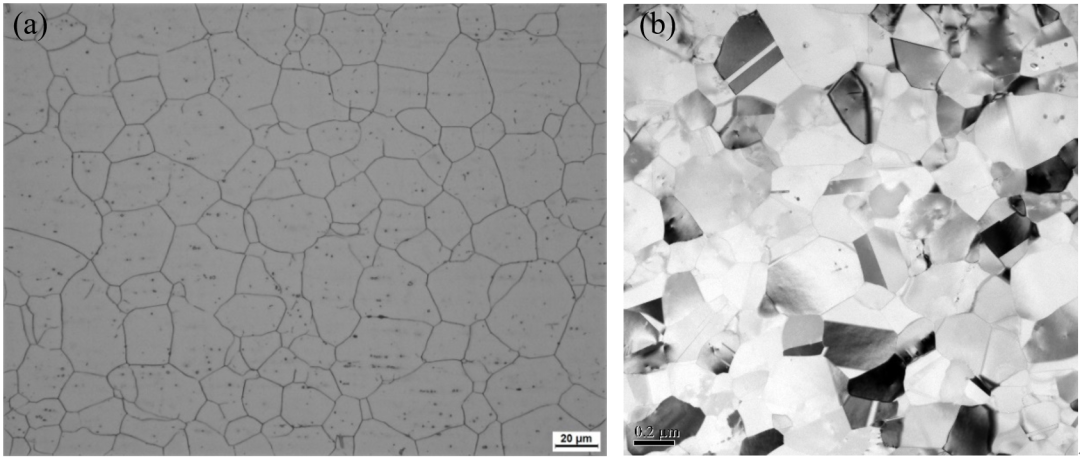

Through the integrated control of hot rolling - cold rolling - annealing, based on the principle of cyclic phase transformation and refinement, the laboratory preparation of 304 stainless steel with nano/submicron crystals (grain size 100-300 nm) has achieved by multi-stage cold rolling annealing (Pic. 1). The plate shape and surface quality is good, and the yield strength reaches 1100MPa.

Figure 1 Initial hot-rolled organization of 304 stainless steel (a) and prepared nano/submicron crystal organization(b)

3 Organization property regulation

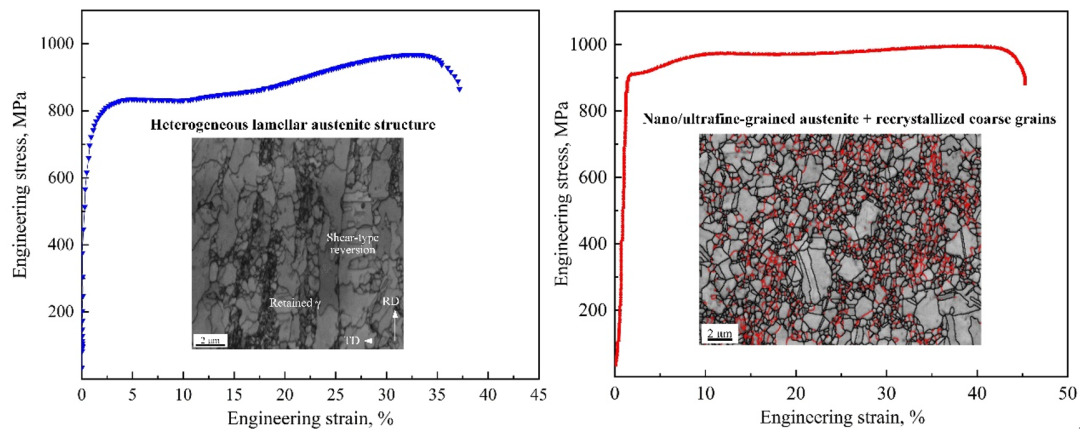

By controlling the cold rolling reduction and annealing process, a small amount of re-crystallization austenitic coarse grain whose size is greater than 1 is introduced into the ultra-fine grain inverse transformation austenite matrix, forming multi-scale nano/submicron crystal structure, and obtaining excellent properties with yield strength of about 900MPa and great elongation of about 45%. By using rapid heating, the cold rolled martensite can be controlled to transform into austenite by shear mechanism, forming a layered heterostructure with high density of dislocations, and good strong plasticity matching. The reason is the coordination of dislocation strengthening, back stress strengthening, TRIP effect and other strengthening mechanisms.

Figure 2 Austenitic tissues with different heterogeneous structures and their engineering stress-engineering strain curves

4 Low temperature superplastic behavior

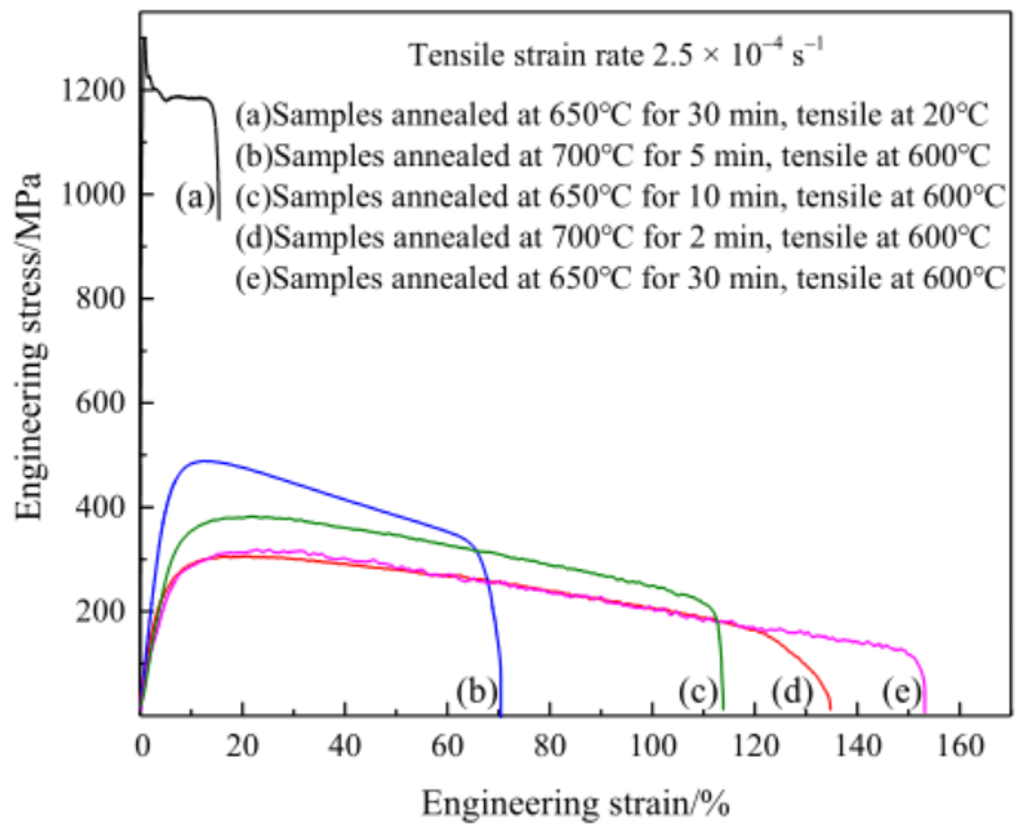

The superplastic behavior of 304 stainless steel with nano/submicron crystals (grain size about 200 nm) at low temperature (<0.5 Tm) has been studied. It is found that it shows superplastic-like behavior at 600 ℃, with elongation>150%. At 630 ℃, it shows typical superplastic behavior, with the maximum elongation exceeding 300%. The superplastic deformation mechanism is grain boundary sliding, and the coordinated deformation mechanism includes grain boundary migration and dislocation sliding. The discovery of low temperature superplasticity further broadens its application in high temperature field.

Figure 3 Tensile curves of nano/submicron crystal 304 stainless steel at different temperatures

5 Research achievements, promotion and application

This research published 8 SCI papers, 3 national invention patents and 2 monographs. Based on the existing process equipment conditions of Benxi Steel Stainless Steel Cold Rolling Dandong Co., Ltd., the industrial preparation of nano/submicron crystalline 304 stainless steel with high strength and high plasticity has been realized, with yield strength ≥900MPa and elongation>30%. The nano/submicron crystalline cold-rolled stainless steel is suitable for rail car body, automobile structure, marine hose and other fields, and its promotion and application are in progress.

Figure 4 Industrial preparation of nano/submicron crystal 304 cold rolled stainless steel