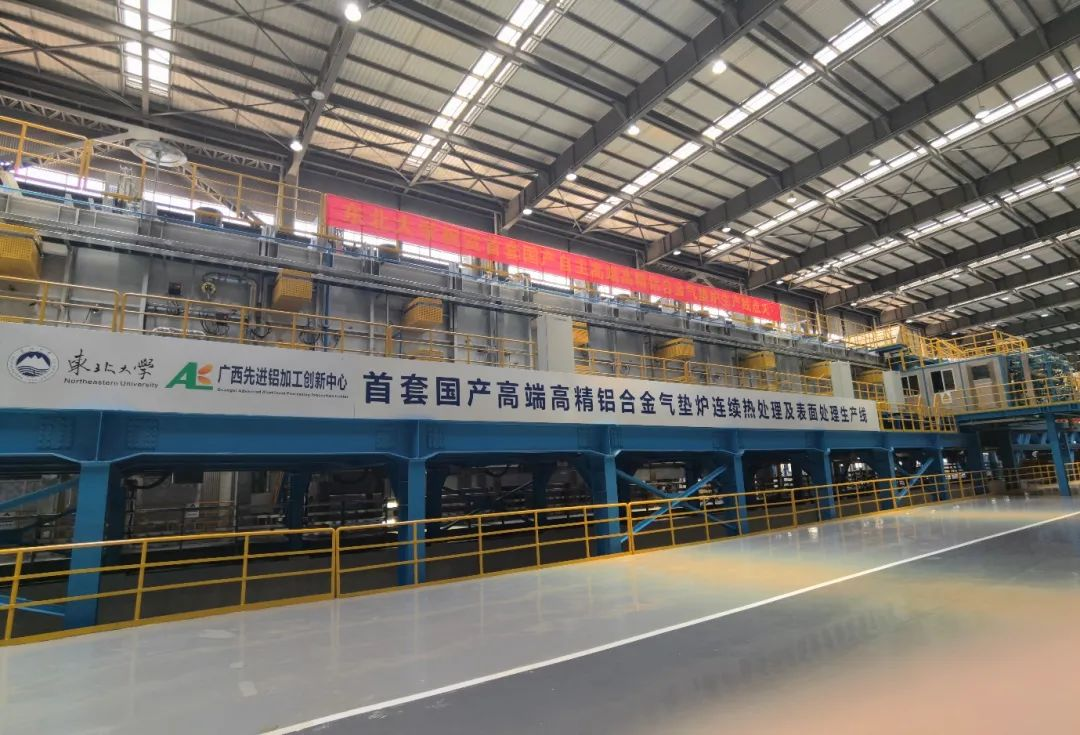

On July 1, 2022, the 2400mm air cushion furnace continuous heat treatment and surface treatment production line jointly developed by the State Key Laboratory of Rolling and Automation (RAL) of Northeastern University, Guangxi Advanced Aluminum Processing Innovation Center and Guangxi Nannan Aluminum Processing Co., Ltd. was successfully ignited. Heads of the Equipment Industry Development Center of the Ministry of Industry and Information Technology, the Department of Industry and Information Technology of Guangxi Zhuang Autonomous Region, the Department of Science and Technology, Nanning Municipal Government, the Bureau of Industry and Information Technology, the Office of the Expert Advisory Committee, Guangxi Investment Group, Nanning Industrial Investment Group, Guangxi Nannan Aluminum Processing Co., Ltd., and other units, as well as Tang Lixin, academician of the CAE Member, Vice President of Northeastern University, and heads of relevant departments, attended the ignition ceremony.

▲ Project ignition ceremony

Wei Qiang, Chairman of Guangxi South-South Aluminum Processing Co., Ltd., said that South-South aluminum processing insisted on taking innovation as the first driving force to lead the development of enterprises, and jointly developed national major short plate equipment with Northeastern University and Guangxi Advanced Aluminum Processing Innovation Center, focusing on promoting the construction of major short plate equipment projects for high-end high-precision aluminum materials. The completion and landing of the first set of air cushion furnace is of milestone significance. It has achieved a technological breakthrough in the core and key equipment of domestic independent research and development of air cushion continuous heat treatment, surface treatment and other processes from scratch, promoted the solution of the neck problem of domestic aluminum alloy sheet heat treatment equipment, and made an important contribution to serving the major national strategy and industrial development.

Wang Guodong, an academician of the CAE Member and professor of RAL of Northeastern University, said in an interview with Guangxi TV that the heat treatment equipment of the air cushion furnace is a national choke problem. This ignition of the air cushion furnace marks that China can independently produce aluminum alloy air cushion furnaces, break foreign monopoly, and key core technologies are in our own hands. At the same time, the majority of scientific and technological workers should make contributions to national development, self-reliance, collaborative innovation, give full play to the advantages of the socialist system, and tackle the national bottleneck problem.

Tang Lixin pointed that President Xi of PCR gave great expectation to the high-end aluminum equipment localization when he visited Nannan Aluminum Processing Co., Ltd.. Through the cooperation between RAL and Nannan Aluminum Processing Co., Ltd. for many years, the successful development and ignition of the first set of aluminum alloy air cushion furnace have practiced the spirit of President Xi’s important speeches with practical actions. The ignition of the air cushion furnace project plays a very important leading role in the process, technology, equipment and products of other industries. Tang Lixin stressed that Northeastern University attaches great importance to the transformation of scientific and technological achievements, and always adheres to the organic combination of technological achievements with the needs of enterprises and the needs of the country to make due contributions to the regional economy, the main battlefield of the national economy and the major needs of the country.

Air cushion continuous heat treatment furnace, referred to as air cushion furnace for short, is the core equipment for the production of high-end high-precision aluminum alloy strips for automobiles and aviation. It can achieve high-quality heat treatment with zero surface defects, and has long been monopolized by a few foreign companies. Its core equipment technology and process model control system are strictly blocked, the production line equipment is expensive, and the equipment manufacturing, installation and commissioning cycle is long, which seriously hinders the production and research and development of high-end high-precision aluminum materials in China's aluminum processing industry.

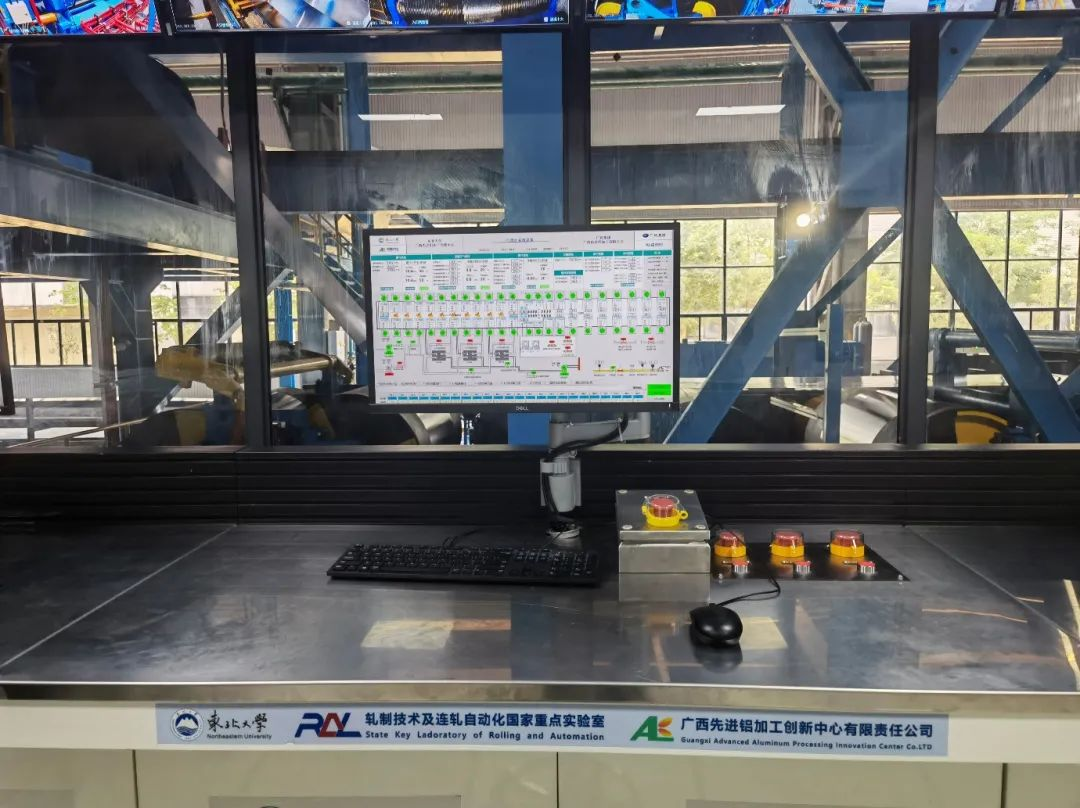

The R&D team of State Key Laboratory of Rolling Technology and Continuous Rolling Automation of Northeastern University has implemented the innovation model from basic research - technology development - engineering transformation - industry promotion (R&DES) around major tasks. Since 2009, Li Yong and others have been conducting research on the mechanism of fast solid solution aging of aluminum alloy air cushion, the mechanism of air cushion nozzle air cushion floating dynamics and uniform heat exchange, and the simulation and optimization of air cushion furnace structure; in 2012, Li Yong, Li Jiadong and a group of young teachers undertook the task of developing the electrical control system for the whole line of imported air cushion furnace production line of South-South aluminum processing. In 2015, the installation of equipment was completed, the control system was put into use, and the whole line was successfully put into operation; in 2013, the development of pilot equipment for air cushion furnace was started, and in 2014, the pilot equipment for large air cushion furnace was successfully developed; in 2014, the development of surface treatment unit for aluminum alloy automobile plate of South-South aluminum processing imported air cushion furnace production line was undertaken, and in 2016, the development and installation of equipment and commissioning were completed, and the first set of domestic aluminum alloy automobile plate Surface treatment unit, successfully put into use; in 2019 began China's first 2400mm aluminum alloy air cushion furnace continuous heat treatment and surface treatment production line full set of equipment system localization and engineering work; now after thirteen years of efforts, finally realize the key core equipment aluminum alloy air cushion furnace and the whole line of complete sets of equipment and the whole line of process model control system localization, breaking the foreign monopoly.

Since the implementation of the project, it has received strong support from the Ministry of Industry and Information Technology, Guangxi Zhuang Autonomous Region, Nanning Municipal Government and Northeastern University and has been approved as a national major short board project. NANAN aluminum processing 2400mm air cushion furnace continuous heat treatment and surface treatment production line is a large aluminum alloy strip heat treatment line mainly for the production of aviation plates and auto body plates. The total length of the line is 378m, and the line equipment includes double uncoiling unit, stitching and crescent shear unit, disc shear unit, cleaning unit, entrance live set unit, air cushion heat treatment furnace, drawing and straightening unit, acid and alkali washing and passivation unit, exit live set unit, pre-aging furnace, electrostatic dry lubrication unit, oil film meter, double coiling unit and other equipment, with cleaning, edge cutting, continuous solution, water cooling quenching, air cooling quenching and drying, bending and straightening, acid and alkali washing and passivation, pre-aging, dry electrostatic lubrication and other functions. The overall design of the line is internationally advanced, with an annual production capacity of 65,000 tons, processing products of 0.4~4.0mm thick wide aluminum alloy strips, which can provide qualified thin strips for key fields such as domestic large aircraft, new energy vehicles, 3C and pan-semiconductor.

During nearly 30 months of project construction, the R&D team of Northeastern University's RAL laboratory project overcame difficulties and joint research and development, and overcame "gas dynamics and dynamic equilibrium floating mechanism of wide metal strip air cushion", "strong convection heat transfer and air flow distribution mechanism ", "Large air volume double outlet high temperature circulating hot air blower", "High strength and corrosion resistant aluminum alloy high temperature strip fast moving continuous quenching", "High strength and high formability and high strength and high toughness corrosion resistant aluminum alloy Rapid Solution Ageing Mechanism", "Chromium-free Surface Passivation of Aluminum Alloy Automotive Sheet", "CPS Control System for Continuous Heat Treatment and Surface Treatment of Large-Scale Strip" and other key technologies, and developed China's first set of "CPS Control System" for the localization of aluminum alloy aviation sheet and automotive sheet, It has developed the first set of "neck" equipment and system for the localization of aluminum alloy aviation and automobile plates, which has laid a solid and reliable technical foundation for the development of the project.

The 2400mm air cushion furnace continuous heat treatment and surface treatment production line of the national major short board equipment project is the first high-quality aluminum alloy strip continuous heat treatment and surface treatment production line independently developed, designed and manufactured in China, based on the domestic industry chain, supply chain and innovation chain, realizing the core components including air cushion heating system, cooling system, fan, burner, dry electrostatic oiler, table inspection, deflection detection original parts, process The core components including air cushion heating system, cooling system, fan, burner, dry electrostatic oiling machine, gauge inspection, deflection detection components, automatic control system, etc. have been developed independently, breaking through the "neck" problem of China's core equipment in the development and manufacturing technology of air cushion continuous heat treatment furnace, fundamentally solving the shortcomings of the domestic high-quality aluminum plate and strip heat treatment production line and achieving independent innovation! The successful development of domestic aluminum alloy air cushion furnace production line will accelerate the independent transformation capability of high precision and high performance aluminum alloy sheet and strip product R&D results, and strongly enhance the supply guarantee capability of key aluminum alloy materials in key fields such as aerospace, new energy automobile, 3C and pan-semiconductor in China.