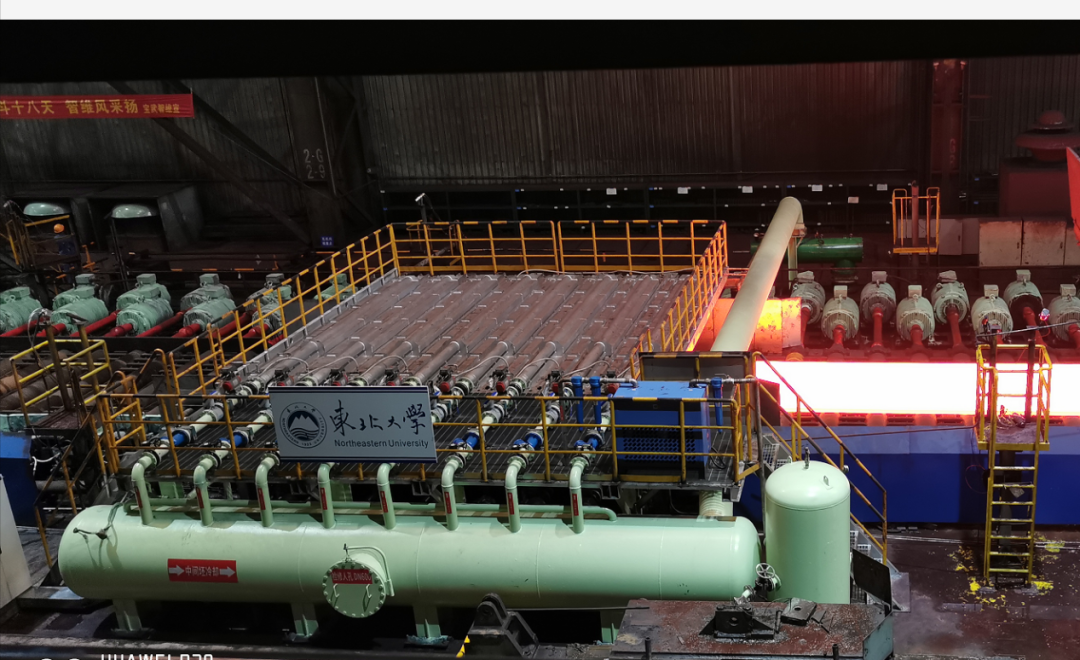

In September 2021, the thermal load test run of the post rolling control cooling system and intermediate cooling system of Chongqing Iron and Steel 4100mm thick plate line undertaken by State Key Laboratory of Rolling and Automation (RAL) of Northeast University was successful.

The post rolling control cooling system and intermediate cooling system of Chongqing Iron and Steel 4100mm thick plate is a key project of equipment upgrading and transformation in 2021. In May, based on the leading advantages of RAL in the cooling technology after rolling of medium plates, and on the basis of full technical exchanges on the production line, Chongqing Iron and Steel and RAL signed two general contracts for the post rolling control cooling system and the intermediate billet cooling system. In the middle of September, the thermal load test run of the production line was successful at one-time, marking that the system was officially put into operation and the project entered the production process commissioning stage. RAL completed the design, manufacturing, installation and commissioning of the two projects with quality and quantity guaranteed in a relatively short period of time, ensuring the normal implementation of the construction tasks during the annual overhaul of Chongqing Iron and Steel.

Pic. Post rolling control cooling system

Pic. Intermediate cooling system

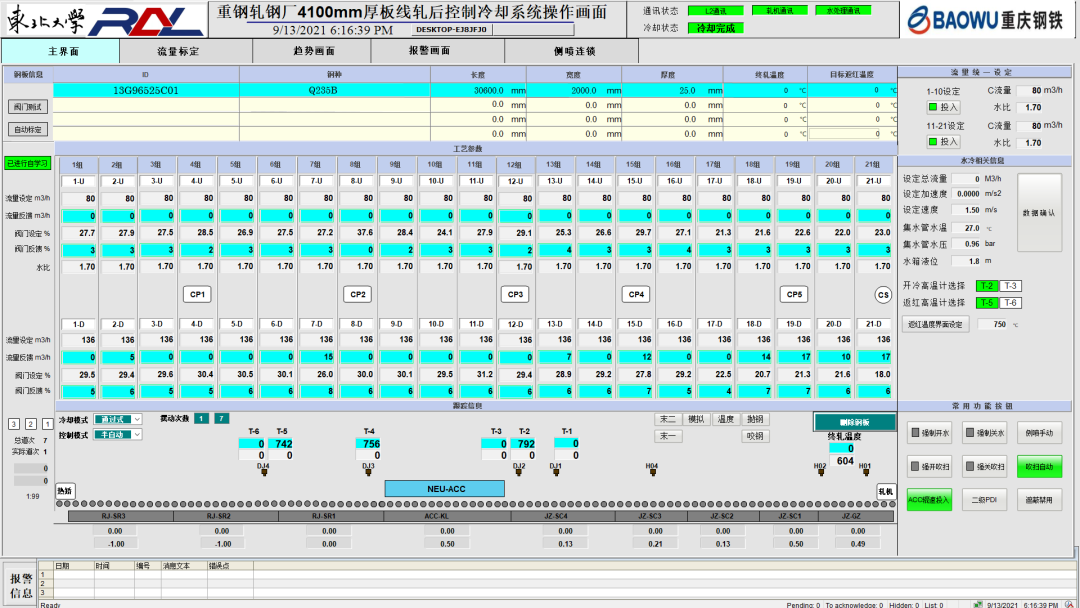

The original post rolling cooling device of Chongqing Iron and Steel 4100mm production line was built and put into use in 2009. The cooling intensity and uniformity could not meet the production requirements, and the model control accuracy also needed to be improved. For this, according to the actual situation on site and the needs of production and R&D, Northeastern University continued to innovate cooling technology and transform scientific and technological achievements, and designed a new post rolling controlled cooling system and intermediate billet cooling system. The system adopted optimized high-density cooling header, integral stainless steel material and independent detachable nozzle. Advanced magnetic induction valve positioner was selected for valve control, which had stable performance and high control accuracy. On this basis, high-precision flowmeter was equipped to achieve high-precision flow control of each header, laying a solid foundation for high-quality implementation of the cooling process. The horizontal water crown design was adopted for the cooling header to ensure the horizontal cooling uniformity of the steel plate. The head and tail shielding technology and roller table micro acceleration function were adopted to improve the longitudinal cooling uniformity of the steel plate. At the same time, a 1+2 dimensional temperature field calculation model and a deep self-learning method based on VSG intelligent model were developed according to the characteristics of the cooling system, such as multiple parameters and easy interference. The number of learning samples was greatly reduced, the system control accuracy was rapidly improved, and communication with the rolling mill and the straightener area was established. Based on the different steel grades, specifications and temperatures, the automatic intelligent cooling function has realized.

Pic. Operation interface post rolling control cooling system

Pic. Photos of high density nozzle spraying water

The 4100mm thick plate production line of Chongqing Iron and Steel has obvious regional advantages. The smooth operation of the post rolling control cooling system and the intermediate billet cooling system ensures the high-quality implementation of the product cooling process of the production line, improves the cooling intensity and the control accuracy of the cooling process parameters, improves the cooling uniformity, and provides basic conditions for the high-precision control of the whole process temperature of the production line. It also laid the equipment foundation for the research and development of high quality medium plate products.

Since RAL of Northeast University developed the advanced cooling (ultra fast cooling) system for medium plates, it has been successively applied to Nanjing Steel 5000, Shougang Jingtang 4300, Shangang Rizhao 3500 and other production lines, realizing a full range of TMCP with a thickness of 6 mm~150 mm and a width of 2000~5000 mm, as well as mass and stable production of heat treatment on the line. It has become a common technology covering the production of hot rolled high-end plates and strips, and has solved problems of high strength steel plate shape, direct quenching and other aspects, which has made great national contribution that a state key laboratory should have made!