60 years ago, car bodies were almost made of a single steel: low-carbon mild steel. It is needless to say that the simple and comfortable use of low carbon mild steel brings to this system in the automobile industry. However, the increasingly stringent crash safety regulations and the pursuit of improving fuel economy have broken the comfort of the system. If low-carbon mild steel has to be continued to use, the thickness of steel plate must be increased to make up for the lack of material strength, which will increase the weight of the car body, and lead to increased fuel consumption.

Driven by the automobile industry, advanced high-strength steel has developed rapidly: high-strength low-alloy steel (HSLA) was applied in the 1980s, dual phase steel (DP) has been widely used since the 1990s, ultra-high strength AlSi coated hot forming steel (PHS) has been rapidly popularized since 2000, and the third generation of advanced high-strength steel represented by quenching distribution steel (Q&P) has been gradually used in 2010. High strength steel replaces low carbon mild steel in the form of thinner part thickness, achieving the effect of reducing weight without sacrificing collision performance.

The vigorous development of new steel types provides wide space for material selection and structural design for car body engineering designers. It seems that every new steel type has its application in the automobile structure, so people naturally shout out the slogan of the right material is used in the right place. However, body manufacturing and system management are more complex in some aspects than ever before. It is a typical systematic accident that the right materials are used in the right place: the entropy of the subsystem decreases, but the entropy of the whole system rises. Today's steel body in white involves hundreds of parts, which are made of more than ten different components and more than ten different thicknesses of steel plates. The following are some facts about the entropy increase of the system: 1. The production of multiple steel grades has increased the difficulty of steel mills in optimizing process parameters and order management in chemical metallurgy, inclusion control, physical metallurgy and other processes; 2. The existence of multiple steel grades increases the workload of technical verification and material certification for automobile companies; 3. The existence of multiple steel grades makes the most classic stamping, welding and painting links in automobile manufacturing extremely complex. Engineers almost need to formulate corresponding manufacturing specifications for each steel grade of each thickness (especially for the welding of dissimilar materials, each welding is a small metallurgical process with different materials mixed, and its complexity is self-evident); 4. Scrap steel sorting/ recycling/ reuse of scrapped car bodies has become a challenge. Therefore, every practitioner is yearning for the era of using single low-carbon mild steel.

Under the background of dual carbon, the low carbon (actually, the entropy reduction of the system) of automobile manufacturing has become an important topic of industry development. We can't help recalling that we also lived in the era of low entropy (using single low-carbon mild steel). Rethinking in the context of the whole industrial chain from material production to automobile manufacturing, we believe that the core of the innovation of traditional automobile body design and manufacturing is to design a new model and return to the low carbon mild steel, which was once a single steel type, to reflect all the advantages of the low entropy system. The enabler of this mode is to develop a new steel or a new type of steel, whose strength meets all the requirements of automobile body structure design. Its manufacturability is suitable for the efficient production of most parts by stamping, and its manufacturing cost should be low enough, so low that the main engine plants around the world have the power to adopt such a new scheme.

In view of this major issue of the industry development, materials scientists from General Motors China Academy of Science, Northeast University, Nanjing University of Technology, Yucai Tang (Suzhou) Materials Technology Co., Ltd. and Hong Kong University took a different approach and proposed to replace the existing various automobile steel components with a single steel alloy component, namely the concept of UniSteel. UniSteel can flexibly obtain various derivative steel grades with excellent performance through heat treatment. It is also a single component steel body in white. The performance of UniSteel body will be far better than that of the single low-carbon mild steel body in white in the 1960s. At the same time, UniSteel has also solved most of the systematic problems in today's multi steel body manufacturing, such as the lengthy steel certification process and material/ part/ subsystem verification. The UniSteel concept is a specific case of material normalization proposed by Academician Luca and others, which is expected to innovate the body manufacturing mode of the global automotive industry, and reduce the complexity of various links such as the design, procurement, production and manufacturing of steel body in white through the normalization of steel grades.This achievement was recently published on Science Advances, a sub journal of Science. The first author is Dr. Lu Qi, a senior researcher of General Motors China Academy of Sciences and a visiting professor of Northeast University. Associate Professor Lai Qingquan of Nanjing University of Technology is the co-first author. The corresponding authors are Wang Jianfeng, President of General Motors China Academy of Sciences, Professor Xu Wei from Northeastern University and Professor Huang Mingxin from Hong Kong University. The authors of the paper also include Dr. Xiong Xiaochuan and Professor Yi Hongliang from Yucai Tang (Suzhou) Materials Technology Co., Ltd., and two doctoral students of Professor Xu Wei's research group, Chai Zhisong and Wei Xiaoliao.

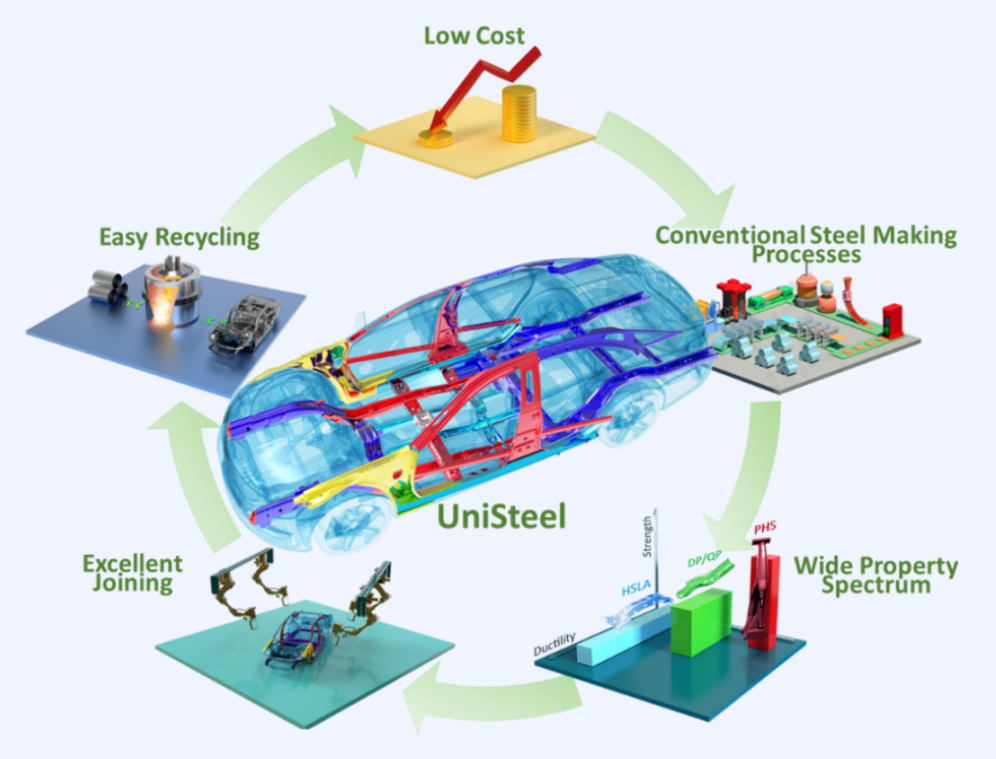

Figure 1. Requirements to be met for the UniSteel concept to become a viable material solution for steel body-in-white manufacturing

The UniSteel concept needs to meet a series of system performance requirements, as shown in Figure 1. Firstly, UniSteel must be low-cost and easy to recycle. Secondly, it must be able to conduct large-scale production through the current mature steel process, including steelmaking, continuous casting, hot rolling, pickling, cold rolling and annealing. Then, UniSteel parts must be able to use the existing heat treatment and machining processes to obtain the required structure and properties. Finally, Unisteel derived steel grades should have good resistance spot welding performance. Based on the above considerations, the researchers learned from the design concepts of several current major advanced high-strength steels, selected low-cost carbon (C), manganese (Mn), silicon (Si) and chromium (Cr) as the main alloy elements, and used niobium (Nb) as the microalloy element. Through mature heat treatment process, ferrite, martensite, austenite, nano carbide and other phases were flexibly combined to obtain the corresponding microstructures of HSLA, DP, Q&P and PHS steel grades derived from Unisteel, as shown in Figure 2. At present, UniSteel has successfully conducted hundred ton industrial scale tests in four steel plants in China and the United States, and has manufactured hot rolled and cold rolled coils of several thicknesses using the existing automobile steel production process. The cumulative trial production scale is close to 1000 tons. Among them, two steel plants adopt a short process steel production process based on electric furnace steelmaking, which uses about 50% of scrap steel, thus greatly reducing carbon emissions per ton of steel.

Figure 2 Microstructure of Unisteel-derived HSLA, DP, Q&P and PHS steel grades

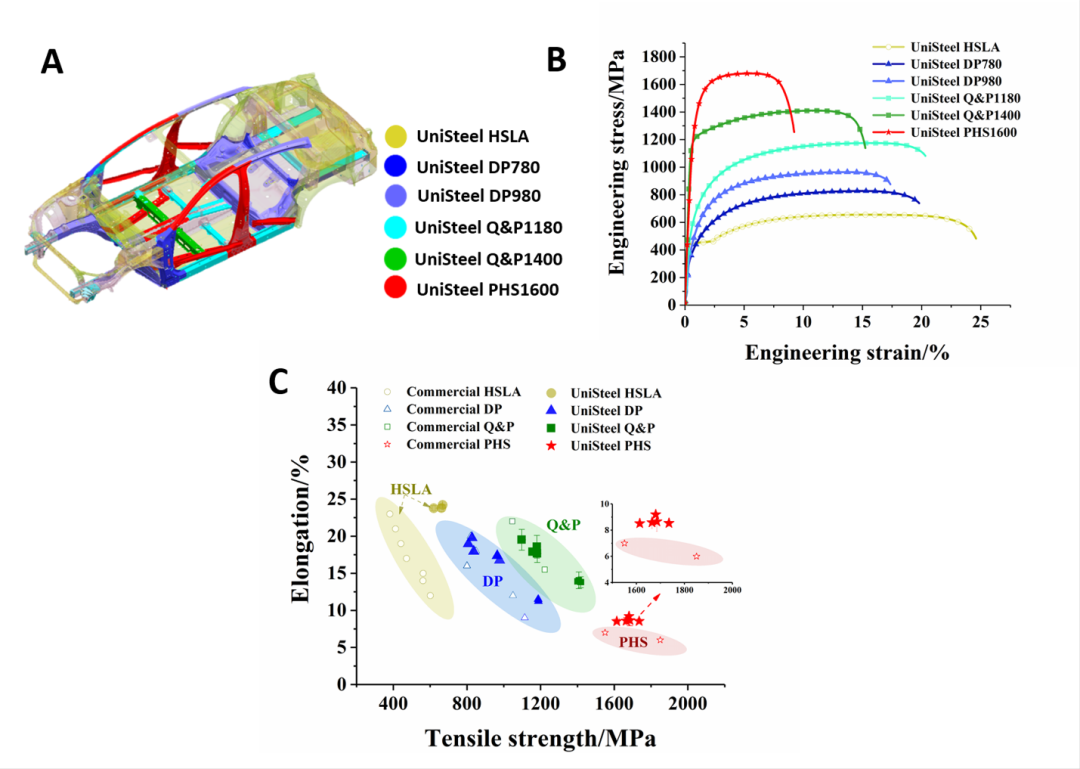

The tensile properties of UniSteel derived steel grades (HSLA, DP, Q&P and PHS) are shown in Figure 3. Through reasonable use of precipitation strengthening, solid solution strengthening, fine grain strengthening, phase transformation strengthening and residual austenite transformation plasticization and other mechanisms, all UniSteel derived steels have obtained excellent mechanical properties. Its tensile strength ranges from 600 MPa to 1680 MPa, and the corresponding elongation at break ranges from 25% to 9%, indicating that UniSteel can obtain a wide range of mechanical properties. At the same strength level, the elongation of HSLA, DP and PHS derived steel grades of UniSteel is higher than its corresponding commercial products of the same kind. In addition, taking PHS steel of UniSteel as an example, the front bumper anti-collision beam was trial produced on the production line through the conventional hot stamping process. Its intrusion resistance is better than the commercial hot formed steel product 22MnB5, and the weldability of the hot formed steel has also been preliminarily verified.

Figure 3. (a) Body-in-white design using UniSteel-derived HSLA, DP, Q&P and PHS. (b) Tensile properties of UniSteel-derived steel grades. (c) Comparison of tensile strength and elongation of UniSteel-derived steel grades with some existing commercial grades.

To sum up, by ingeniously designing the alloy composition of UniSteel, the steel grades with single composition can obtain different microstructures through the existing mature production process, thus providing more excellent mechanical properties than the existing steel grades and realizing the lightweight of the steel body in white. The concept of UniSteel represents a new technology path, which can greatly simplify the design, manufacturing and recycling of steel BIW. The concept of UniSteel also fundamentally challenges the traditional understanding that appropriate materials are used for appropriate parts. In fact, UniSteel put forward the concept of appropriate performance is used for appropriate parts. The ingenious composition design and the accumulation of traditional physical metallurgy knowledge for a century perfectly realizes the 1 and N mapping relationship between composition and performance. The authors hope that the UniSteel concept is expected to revolutionize the body design and manufacturing model of the global automotive industry, significantly reduce the carbon emissions of body steel while lightening the body, and thus help the automotive industry achieve carbon neutrality in a short time.