In the production process of hot continuous rolling, most of mathematical models for field operation are mechanism models. Because the changes of process conditions and equipment operation status often cause changes in production conditions, and the relationship between process input conditions, state variables and control objectives is very complex, these mechanism models are not suitable for complex dynamic processes, and the prediction accuracy of the model is not high when the process conditions and operation status change, and it is difficult to accurately perspective the process, equipment, quality and also the complex relationship between key parameters. Especially under the unsteady working conditions such as the first coil after roll change,or specification change, the wide and thin gauge rolling, the large deviation of strip steel thickness, width and shape often occurs, resulting in a large number of out-of-tolerance product size and shape, leading to product degradation, scrap and even production accidents. Therefore, how to improve the model control accuracy under these non-steady conditions is a difficult problem to be solved urgently in the hot rolling control system.

Relying on the existing automation and information system and deeply integrating the data-driven model and mechanism model, the dynamic digital twin model of the hot tandem rolling process is developed for the first time and the CPS control system platform is established, which improves the ability of the rolling process to analyze complex and variable conditions in situ and improves the dimension control index of the hot tandem rolling process.

1. Big data platform and data governance

The digital sensing technology is used to intelligently process and integrate the data of hot continuous rolling production process, and the machine learning algorithm is used to carry out data mining. The complex relationship between key parameters such as process, equipment and quality is accurately seen from the massive data. The analysis and mining module is developed, the data distribution map with low hit rate is established, and the model error distribution law in the specification switching process is found. It provides the basis for the subsequent data-driven model node selection and model optimization, and realizes the analysis, judgment and tracing of the anomalies in the dimension control process.

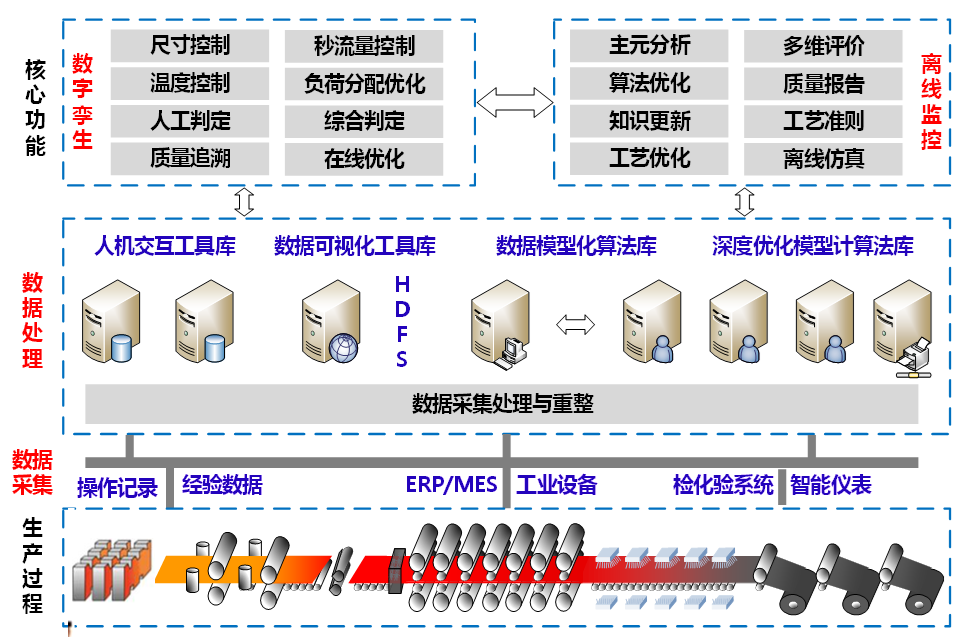

Fig. 1 Mathematical twinning system framework of hot rolling process

2. Construction of twin platform of process control system

Hanbao 2250mm hot continuous rolling line has been put into operation for more than ten years, but it has encountered a bottleneck in further improving the accuracy of three-dimensional control under non-steady working conditions. RAL plate and strip rolling and intelligent research group has carried out a lot of field research and system optimization design. With the strong cooperation and support of field process, model and automation personnel, it has developed a high-precision digital twin model. Based on the existing control system hardware, and using the existing industrial network architecture, it has built a CPS control system platform for the hot rolling process, which realizes the parallel calculation of the new system and the original system, and has self-organization, self-configuration and self-optimization. It forms a knowledge base, model base and resource base, which enables the system to continuously evolve and improve itself, and realizes system autonomy. When the setting accuracy of the digital twin model meets the requirements, the new digital twin model and the original model can be automatically switched. The system control logic diagram is shown in Figure 2.

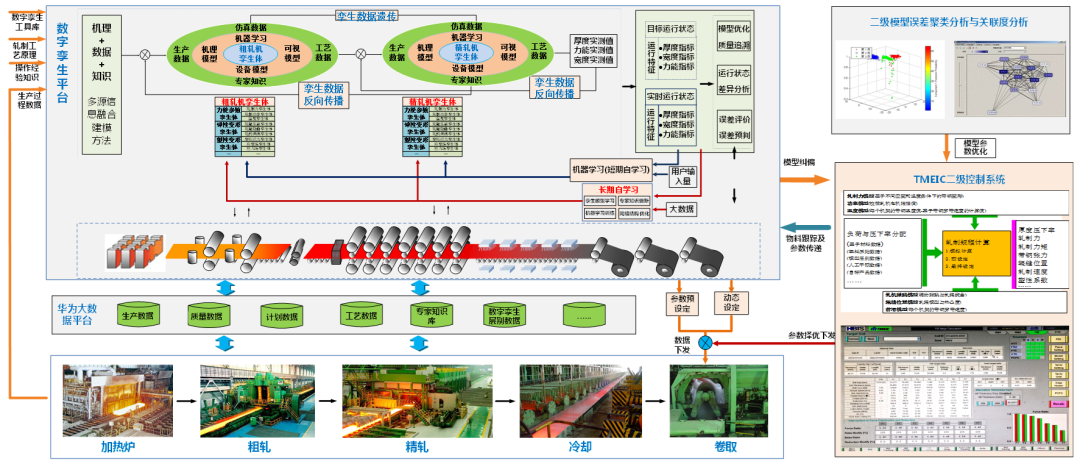

Fig. 2 CPS system framework of hot rolling process

3. Three-dimensional digital twin model of data-driven fusion mechanism and CPS system application

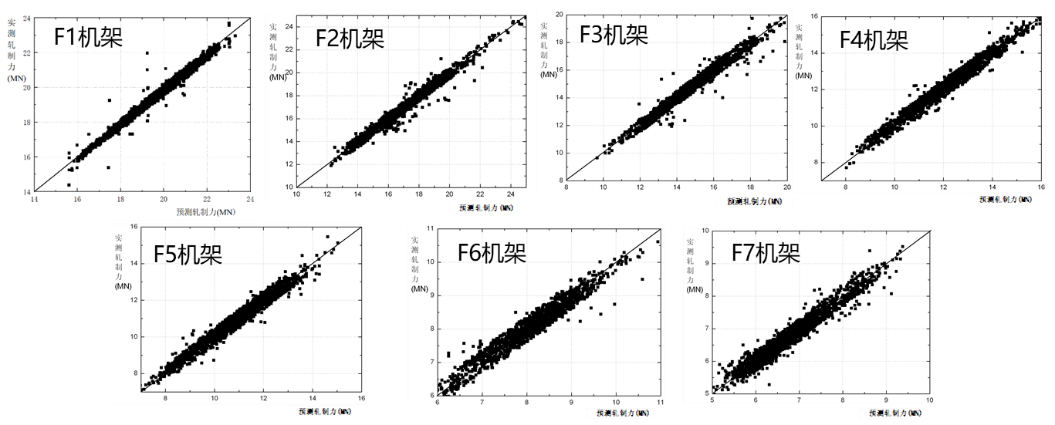

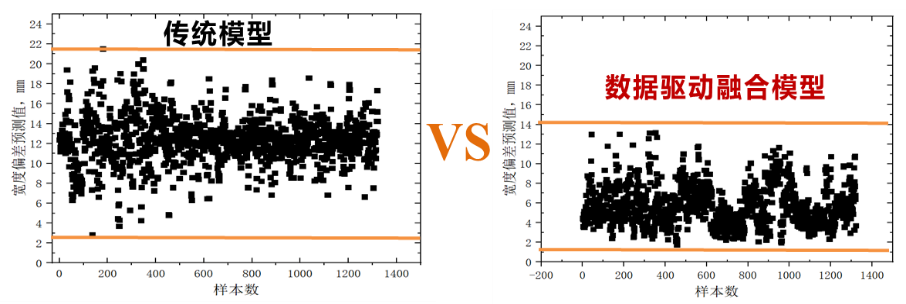

Based on the actual needs of the site, the digital twin model system and CPS feedback optimization module software based on multi-source data and multi-model fusion such as instrument data, numerical simulation data, mechanism model, machine learning model, etc. are constructed, which improves the setting accuracy of rolling force and three-dimensional dimension. The above method has been successfully applied to the 2250mm hot continuous rolling production line in Hanbao. The actual production data of about 35000 tons of products in the past two months have been collected for data statistics and analysis. The effect of model setting is shown in Figure 3 and Figure 4. After the gauge change, the setting accuracy of the first roll rolling force has been increased from 91.6% to 95.2%, and the comprehensive setting accuracy of the rolling force has been increased from 93.4% to 95.4%. In order to further improve the control accuracy of the three-dimensional size of the product, a mechanism and data-driven integration of the rolling mill bounce, roll wear and thermal expansion setting model have been developed. Through rolling optimization, the control accuracy of thickness and width has been improved. The thickness hit rate has been increased from 95% to more than 97%, the first roll width hit rate has been increased from 90.5% to 94.5%, and the comprehensive width hit rate has been increased from 92.3% to 96.5%. After the improvement of the above quality indicators, the secondary product rate of the product due to the three-dimensional size control accuracy decreased by 26.3%.

Fig. 3 Rolling force prediction of data-driven fusion mechanism

Fig. 4 Width prediction of data-driven fusion mechanism

The practical application shows that the data-driven model can significantly improve the poor applicability of the traditional mechanism model to complex dynamic processes, and solve the problem of low model setting accuracy caused by unclear mechanism, complex process and high product quality requirements in the process of strip rolling. In the next step of work, we need to realize the iterative optimization and parameter improvement of the digital twin model through the two-level closed-loop system based on the currently built digital twin model and CPS application platform. Among them, the inner loop system is used to achieve high-precision setting of production parameters for each process of the hot rolling production line through machine learning algorithm during the operation of the digital twin system. The outer loop system realizes the adaptive optimization of the digital twin model system, the update of the expert rule base, and the training and structure optimization of the network model of the machine learning algorithm through the machine learning algorithm during the operation of the digital twin model. This technology can not only improve the three-dimensional size control accuracy of the plate and strip rolling process, but also has universal significance for the intelligent upgrading and quality improvement of the long profile and non-ferrous metal rolling production line.