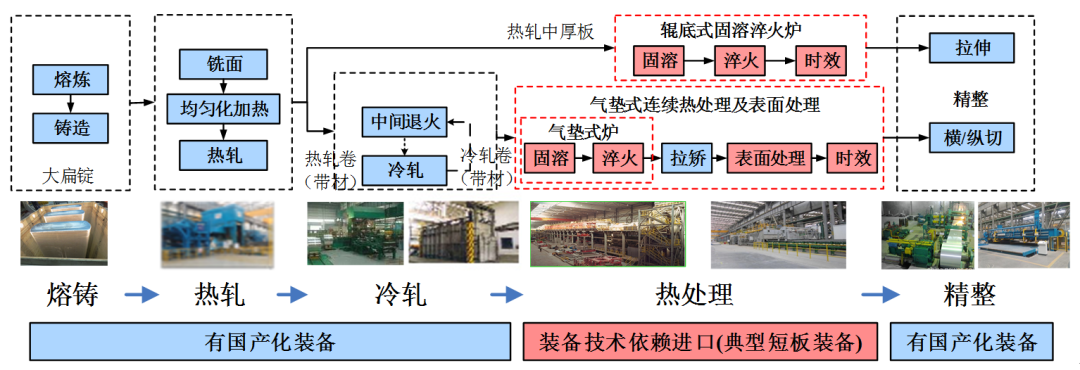

China is the largest consumer of aluminum and copper products in the world, but the product structure is quite different from that of developed countries in Europe and the United States. There is a surplus of low-end products and a shortage of high-end products. High-end high-precision aluminum alloy materials, represented by aircraft skin, wing panels and automobile body sheets, have been the weak areas of China's non-ferrous industry and rely heavily on imports. In the production process of such high-end high-precision aluminum products, the equipment and technology related to the smelting - casting, hot rolling, cold rolling and finishing processes have been basically mastered in China, but the core key equipment such as roller-bottom continuous solid melting furnace and air-cushion continuous heat treatment furnace are still blank. This is of great significance, in order to improve the product competitiveness of domestic aluminum and copper alloy enterprises, help the localization of high-end high precision aluminum and copper products, remove the various constraints of foreign equipment on China's high-performance high precision aluminum and copper alloy materials, and realize the localization of the technology for producing high-end high precision aluminum and copper heat treatment equipment.

Figure 1 Production process flow of high-precision aluminum alloy plate and strip

Therefore, on the basis of breakthroughs in large roller-bottom continuous heat treatment furnaces in the field of steel and iron, the RAL laboratory scientific research team has carried out research and development on the equipment technology of roller-bottom heat treatment furnaces for aluminum alloy medium and thick plates, aluminum alloy and copper alloy air-cushion continuous heat treatment furnaces, as well as key problems in engineering application, aiming at the heat treatment process of high-end high-precision aluminum and copper materials.

The first domestic roller-type heat treatment furnace for aluminum alloy plate

On April 16, 2020, the first set of roller-type solid solution quenching furnace for homemade aluminum alloy plate, which was developed under the auspices of the RAL R&D team of Northeastern University, was successfully ignited and hot tested in Guangxi South-South Aluminum Processing Co., Ltd. (Figure 2). By the end of November 2021, 32000 tons of qualified products of 2024, 7075, 6061 and 6082 plate orders have been produced in a stable batch with domestic roller-hearth furnace, creating an output value of about 150 million yuan. Through the successful implementation of the roller-type heat treatment furnace project for aluminum alloy medium and thick plates, the R&D team has overcome the technical problems such as high-precision high-speed hot air circulation heating system, high-temperature and high-density metal brush roller, high-efficiency and high-uniformity quenching equipment system, and the core components of the equipment are completely independent and localized. The developed equipment has achieved temperature control accuracy ≤± 1 ℃ and furnace temperature uniformity ≤± 3 ℃, meeting the requirements of AMS2750 Class I heat treatment furnace. The quenching shape and performance of high-end aluminum plate are generally superior to imported equipment, and are significantly better than imported equipment in some varieties and specifications, and the energy consumption per ton of product is 16% lower than that of imported electric heating roller hearth furnace. In addition to Guangxi South-South Aluminum Processing Co., Ltd., the equipment technology will also be promoted to Shandong Nanshan Aluminum Co., Ltd. by 2021. The successful application of this equipment has broken the monopoly of foreign equipment technology, achieved the independence of China's aviation grade aluminum alloy plate heat treatment furnace equipment, and provided an important guarantee for the large-scale production of high-end high-precision aluminum products.

Fig. 2 The first set of home-made aluminum alloy plate roller-hearth heat treatment furnace

The first domestic aluminum alloy air cushion furnace production line

The air-cushion continuous heat treatment and surface treatment line is used for continuous solution, quenching, annealing, aging, acid-base cleaning, passivation and other treatment of 2xxx, 3xxx, 5xxx, 6xxx and 7xxx series aluminum alloys. It is the only heat treatment line that meets the requirements for the heat treatment surface quality and performance uniformity of aluminum alloy automobile inner and outer panels, aircraft skin, and high-level IT panels.

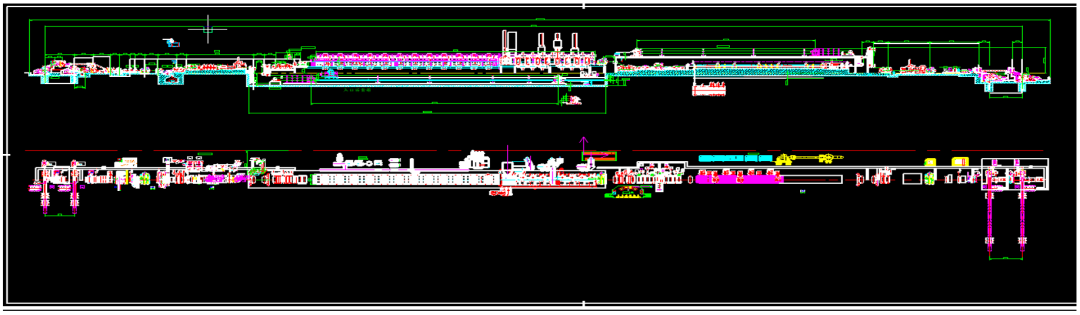

Recently, the first domestic line of continuous heat treatment and surface treatment air cushion furnace for aluminum alloy automotive panels and aviation panels developed and designed by the RAL R&D team of Northeastern University has been designed and manufactured (Fig. 3 and Fig. 4). With the gradual completion of the plant and civil engineering, the installation of the entire production line has officially started in the middle of December 2021. The domestic independent high-end aluminum alloy air cushion furnace production line will start commissioning and operation in the middle of 2022.

Figure 3 The first domestic independent high-end aluminum alloy automobile plate and aviation plate air cushion furnace production line

Figure 4 The first set of domestic aluminum alloy air cushion furnace equipment

The first domestic copper strip air cushion furnace

Copper alloy air cushion furnace is a key equipment for producing high-end copper alloy materials such as integrated circuit lead frame, aerospace and new energy vehicles, and has been monopolized by foreign countries for a long time. On August 6, 2021, Northeastern University signed a strategic cooperation agreement with ChinaLCO Luoyang Copper Processing Co., Ltd., and jointly announced the official launch of the first domestic copper strip air cushion furnace project (Figure 5). After the equipment is successfully put into operation, it will break the monopoly and technical blockade of foreign copper strip air cushion furnace equipment technology, and help the production of high-end copper strip and the research and development of new technology.

Figure 5 Dongda-Luo Copper Cooperation Signing and the First Domestic Independent Copper Alloy Air Cushion Furnace Project Launching

Research and development significance and social benefits

The research and engineering application of advanced heat treatment equipment technology for high-end high-precision aluminum and copper products aims to solve the technical problems of key equipment in the development of complete sets of equipment for domestic high-quality non-ferrous alloy plate, strip and profile heat treatment production line, and reach the domestic and international advanced level, fill in the domestic gap, and promote technical progress in this field. By realizing the independent control of major short plate production lines, reducing the manufacturing cost of high-end high-precision nonferrous products, it can improve the R&D and manufacturing capacity of high-end nonferrous metal materials and new products, promote the application of domestic high-end high-precision aluminum-copper alloy plate and strip products in the manufacturing fields of automobiles, aerospace, high-speed rail, ships, etc., and generate huge economic and social benefits.