With the increasing requirements for environmental protection and weight reduction in the automotive industry, automotive lightweight has become the main trend in the development of the automotive industry. Advanced high strength steel (AHSS), which can greatly improve fuel efficiency and reduce greenhouse gas emissions, is widely used in automotive structural parts. Among them, transformation induced plasticity (TRIP) steel contains metastable retained austenite phase embedded in ferrite matrix, as well as different amounts of martensite and bainite. In the process of deformation, the strain induced transformation from retained austenite to martensite leads to the redistribution of stress, which can meet the good matching of strength and formability at the same time. At present, the production of ultra-high strength (above 1000MPa) TRIP steel needs to go through the cold rolling&annealing process after hot rolling to ensure the residual austenite volume fraction. The process is complex and the production cycle is long. Therefore, it is of great significance to develop ultra-high strength hot rolled TRIP steel products suitable for industrialization by simplifying the process, shortening the production cycle and reducing the cost.

The team of Du Linxiu from State Key Laboratory of Rolling and Automation (RAL), focusing on market demand, cooperated with Chenggang Group of HBIS to establish a key research project of ultra-high strength steel. According to the experimental results of the research group, the C-Si Mn system is adopted, and the composition design of compound addition of Cr, Mo and Ti elements is adopted. The microstructure of retained austenite+bainite was obtained by a new process combining thermo mechanical controlled processing (TMCP) and bainite transformation interval coiling. The 1180MPa hot rolled TRIP steel strip with a thickness of 1.5~6.0mm was successfully trial produced on the 1780 hot rolling production line of Chenggang. The trial products met the yield strength of 700~900MPa, tensile strength of>1180MPa, elongation of>13%, porosity of 28%, and bending of D=3a without fracture. Due to TRIP effect, the plasticity and formability of 10~15% of the deformed steel strip was greatly improved. At the same time, the laser welding performance of all thickness specifications was also excellent. At present, the trial produced thin strip has passed the product certification of FAW Jiefang and BAIC Foton, and has been successfully applied to the front lower protective beam of its commercial vehicles. Compared with the ordinary 700MPa automobile anti-collision beam in the market, it can reduce the weight by 29%, and has the characteristics of high strength, light weight, high safety, energy conservation and environmental protection, which can greatly improve the utilization rate of steel material resources. The successful trial production of 1180MPa hot rolled TRIP steel not only fills the gap in the production of high-strength hot rolled TRIP steel, but also helps Chenggang reach the industry leading level in the production capacity of ultra-high strength anti-collision beam steel.

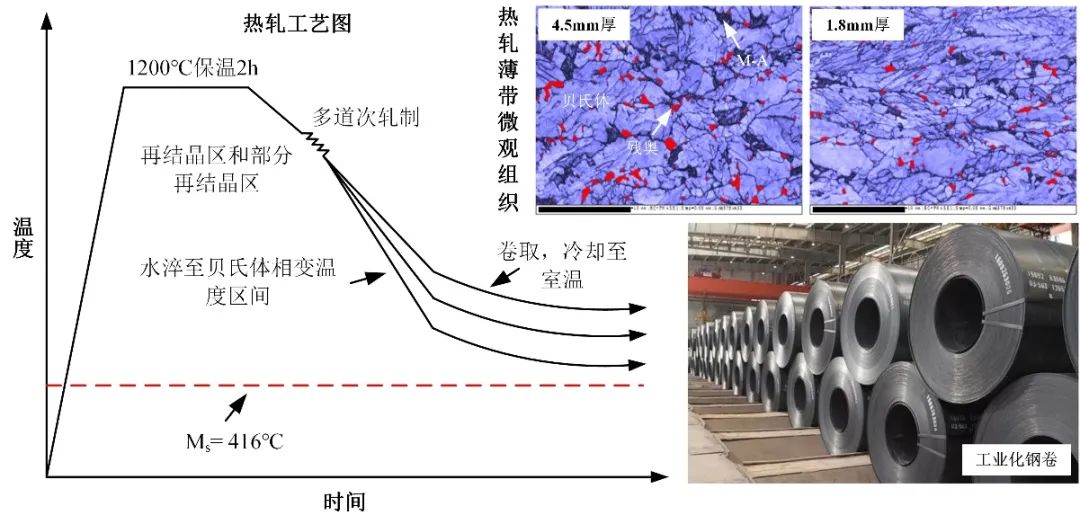

Figure 1 Process roadmap, hot rolled thin strip microstructure and industrialized finished product